ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

5-112

3

Recheck cylinder head flatness, refer to step 4 (e).

4

Recheck cylinder head thickness, refer to step 4 (f).

5

Recheck valve recess in cylinder head, refer to paragraph 4.7.4.b.

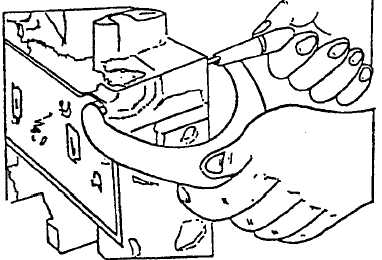

FIGURE 5-91. MEASURING CYLINDER HEAD THICKNESS

__________

WARNING

Compressed air used for cleaning can create airborne particles that may

enter the eyes. Never exceed 30 psi (207 kPa) of pressure. Eye protection

required. Failure to comply could result in serious eye damage or

blindness.

(h)

Clean injection nozzle bores with nozzle bore cleaning tool. Blow debris from bore with

compressed air.

(i)

Clean and measure valve guides as follows:

1

Clean valve guides with plastic brush and a few drops of light oil or kerosene.

2

Measure valve guide inner diameter using telescopic gauge and record

measurements.

3

Calculate valve guide-to-stem oil clearance by subtracting valve stem outer

diameter from valve guide inner diameter. Valve guide-to-stem oil clearance

should be 0.002 - 0.006 in. (0.05 - 0.15 mm).

4

If valve guide-to-stem oil clearance is out of specifications, knurl, thread, and

ream valve guides, refer to step 4 (j).

|

|