ARMY TM 9-2815-259-24

AIR FORCE TO 38G1-125-2

MARINE CORPS 09249A/09246A-24

3-32

(4) Pressure test oil cooler (11) in liquid with compressed air if mixing of oil and coolant is

suspected. Oil cooler should show no leakage when 20-25 psi (140-170 kPa) of air pressure is

applied for a minimum of 30 seconds. If leakage exists, oil cooler must be replaced.

(5) Inspect oil cooler housing (8) and adapter (5) for physical damage, plugging, or leakage.

Replace parts as needed.

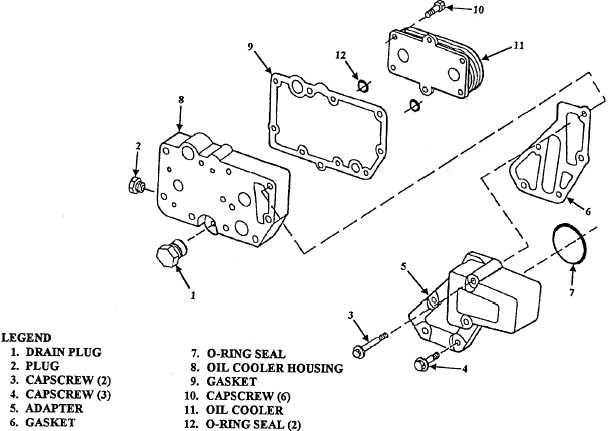

FIGURE 3-10. OIL COOLER ASSEMBLY.

c.

Replacement.

(1) Remove oil cooler (11, Figure 3-10), refer to step a.

(2) Inspect oil cooler assembly, refer to step b. Replace components if physically damaged or leaks

are detected during inspection.

(3) Install oil cooler (11), refer to step d.

d. Installation.

(1) Remove all covering installed during step a (8).

|

|