ARMY TM 9-2815-260-24

AIR FORCE TO 38G1-126-2

MARINE CORPS TM 09244A/09245A-24

5-32

(19)

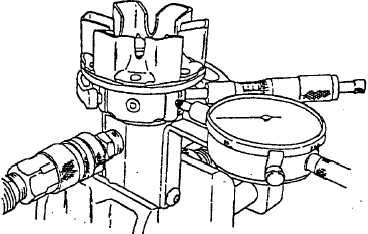

Measure the roller to roller dimension (Figure 5-40) by performing the following:

(a)

Secure roller-to-roller setting fixture (19969) in vise and insert rotor assembly. Connect

dry, clean, filtered, compressed air source regulated to 40-100 psi. (4.5-11.3 kPa) to force

plungers outward until shoes contact leaf spring.

(b)

Using a 1-2 inch micrometer, measure the distance between the outer surfaces of each

pair of opposed rollers. Compare the dimensions to the roller-to-roller dimension called

for on the individual specification, 1.966 in ± .0015 in (49.94 mm ± 0.04mm). Turn leaf

spring adjusting screws clockwise to increase or counterclockwise to decrease the

dimension. The two dimensions must be within 0.0003 inches (0.076 mm) of each other

and the average of both roller-to-roller dimensions must be within 0.0015 of the specified

dimension.

Example: Specified roller-to-roller dimension = 1.966 inches (49.94 mm). One pair of rollers

measures 1.967 inches (49.96 mm) while the other measures 1.964 inches (49.88 mm).

The 2 dimensions are within .003 inches of each other and the average of the 2

dimensions (1.9655 inches) is within 0.0005 inches of the specified roller-to-roller. Since

each leaf spring controls one shoe and roller of each set it may be necessary to

interchange shoes between slots, or install new shoes in each slot, in order to achieve the

proper roller-to-roller dimension and concentricity.

(c)

After the roller-to-roller dimensions are achieved, the roller concentricity must be

checked. Proper concentricity is needed to ensure that all rollers strike the cam lobes at

the same time during pump operation.

(d)

Rotate the rotor until one roller is aligned with in dial indicator plunger on fixture 19969.

Slide the indicator inward until plunger depresses at least 0.010 inches (0.254 mm).

"Zero" indicator by loosening thumbscrew and rotating dial. Recheck "zero" by rotating

rotor to be sure indicator plunger is on high point of cam roller.

(e)

Rotate rotor and observe dial indicator reading for each of the other rollers. Roller

concentricity must be within 0.004 inches (0.1 mm). If not within specification,

concentricity can be achieved through interchanging of shoes or leaf spring positions.

FIGURE 5-40. MEASURING ROLLER TO ROLLER DIMENSION

|

|