ARMY TM 9-2815-260-24

AIR FORCE TO 38G1-126-2

MARINE CORPS TM 09244A/09245A-24

5-50

10

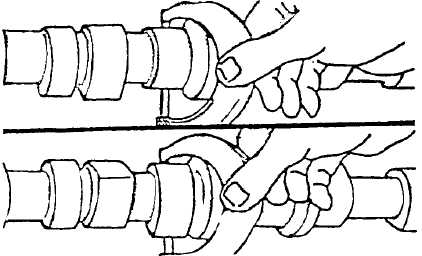

Tighten forcing screw until flange of bushing driver bottoms against face of

block.

11

Remove bushing tool from cylinder block.

12

Check oil supply hole for correct alignment. If oil supply holes are not aligned,

remove and discard bushing and install new bushing.

(c)

Measure and record camshaft bore inner diameter for each remaining camshaft bore.

Camshaft bore inner diameter should be 2.3607 - 2.3617 in. (59.961 - 59.987 mm).

Replace cylinder block if any camshaft bore inner diameter measurement is out of

specification.

(d)

Calculate and record front camshaft journal-to-front camshaft bushing oil clearance by

subtracting front camshaft journal outer diameter from front camshaft bushing inner

diameter. Front camshaft journal-to-front camshaft bushing oil clearance should be

0.0025 - 0.0045 in. (0.063 - 0.115 mm). Replace front camshaft bushing, refer to step c.,

or camshaft, refer to paragraph 5.4.1, as required if front camshaft journal-to-front

camshaft bushing oil clearance is out of specification.

(e)

Calculate and record camshaft journal-to-camshaft bore oil clearance for each camshaft

journal by subtracting camshaft journal outer diameter from camshaft bore inner

diameter. Camshaft journal-to-camshaft bore oil clearance should be 0.0035 - 0.0055 in.

(0.088 - 0.140 mm). Replace camshaft or cylinder block as required if camshaft journal-

to-front camshaft bushing oil clearance is out of specification.

(5)

Measure camshaft lobe height as follows:

(a)

Measure and record height at widest point on camshaft lobe and height at narrowest point

on camshaft lobe using micrometer. Refer to Figure 5-62.

FIGURE 5-62. MEASURING CAMSHAFT LOBE HEIGHT

(b)

Calculate and record camshaft lobe height by subtracting height at narrowest point on

camshaft lobe from height at widest point on camshaft lobe.

|

|