TM 9-2920-243-34

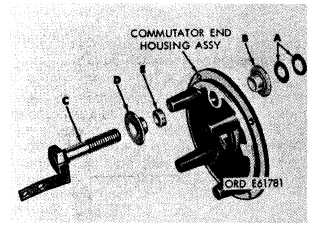

c, Remove two guard washers (A, fig. 3-23) and

insulating bushing (B) from jumper screw (C).

Slide jumper screw out of commutator end

housing and then remove insulating bushing (D)

and sealing ring (E).

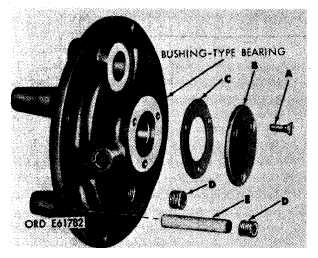

d. Remove three flat head screws (A, fig. 3-24)

cover plate (B), and plate gasket (C). Discard

gasket. Remove two hex-socket head plugs (D)

and oil wick (E).

NOTE

Do not attempt to remove bushing-type

bearing unless inspection (para 3-14 h)

indicates need for replacement.

Figure 3-23. Removing or installing brush rigging jumper

screw and attaching parts.

Figure 3-24. Disassembling or assembly commutator end

housing assembly.

3-13. Cleaning

WARNING

Particles blown by compressed air are

hazardous. Make certain air stream is

directed away from user and any other

persons in area.

a. General. Wash all parts, except those

detailed in 3-13 b through 3-13f below, in dry-

cleaning solvent, Type II (SD-2), Specification P-

D-680, and dry with compressed air.

b. Field Coils. Clean field coils and field ring

thoroughly with a cloth dampened with dry-

cleaning solvent. Be careful not to damage

protective insulation coating. Dry thoroughly

with compressed air (15 psi max.).

c. Armature. Remove loose particles from

armature and wipe with a clean cloth dampened

with dry-cleaning solvent. Clean commutator

lightly with 00 sandpaper and remove all dust

with compressed air.

d. Brushes. Clean brushes with a clean, dry

cloth only. Extreme care must be taken to

prevent dry-cleaning solvent from contacting

brushes.

e. Relay Coil and Shell Assembly. Only ex-

ternal metal surfaces of relay coil and shell

assembly can be cleaned. Clean with a cloth

dampened in dry-cleaning solvent.

f. Non-Metallic Components. Do not clean such

parts as sealing rings, insulating bushings, and

insulating washers. Wipe with a clean, dry cloth.

3-14. Inspection

a. General. Inspect all screws, bolts, nuts,

threaded holes, and plugs for worn or damaged

threads. Replace all worn or damaged parts.

Inspect remaining hardware items and replace

damaged parts.

b. Pinion Housing.

(1) Inspect pinion housing for cracks,

distortion, and burs. Replace if damaged.

(2) Inspect housing bushing-type bearing for

score marks and wear patterns. Check bearing

against limits specified in repair and rebuild

standards (para 3-31 d) and replace (para 3-15 b ),

if worn beyond limits.

(3) If housing bushing-type bearing is

removed (para 3-15 b ), check diameter of bearing

bore in pinion housing against limits specified in

repair and rebuild standards (para 3-31d).

Replace housing if worn beyond limits.

3-9

|

|