TM 9-2920-243-34

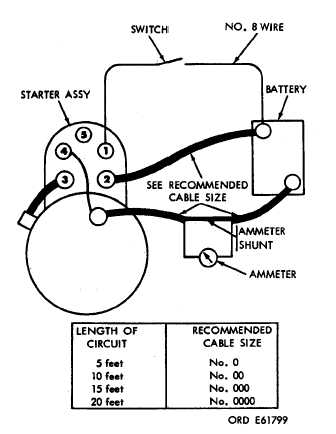

Figure 3-44. Starter test setup.

b. Close switch and measure current draw and

maximum and armature speed should be 6500

rpm minimum.

c.

If a low speed and high current condition

exists, check armature for excessive arcing,

grounds, and shorts. Also examine starter for

armature drag. If drag exists, check for loose pole

shoe screws and tighten as necessary; or,

disassemble starter and check for armature ec–

centricity or faulty bearings.

d.

If low speed and low current condition exist,

inspect starter for faulty connections and for poor

brush contact.

3-28. DELETED.

3-29. Waterproof Test

a.

Place waterproof adapter over pinion

housing. Install adapter and apply 6 psi air

pressure.

b. Allow pressure to build up and then submerge

starter in a suitable water tank.

c. Check for air leaks evidenced by bubbles. No

leakage is permitted.

d.

If leaks are present, disassemble starter,

install new packings and gaskets. Coat packings

and gasket with grease before installation and apply

sealer to all external screws and pipe plugs. Assemble

armature speed. Current draw should be 50 amps

starter and retest for leaks.

Section V. REPAIR STANDARDS

3-30. General

approved for service.

An asterisk (*) in the “Wear

limits” column should be replaced when worn

The repair standards listed in paragraph 3–31 give

beyond limits given in “Sizes and fits of new parts”

maximum, minimum, and key clearances of new or

column. In “Sizes and fits of new parts” column, “L”

rebuilt parts. They also give wear limits, which indicate

indicates a loose fit and “T” indicates a tight fit. All

the point to which a part or parts may be worn before

dimensions are given in inches unless otherwise

replacement, for maximum service with minimum

specified.

replacement. Normally, all parts which have not

3-31. Wear Limits

been worn beyond dimensions shown in “Wear

limits” column or damaged from corrosion will be

All reference letters are keyed to figure B-2.

3-20 Change 1

|

|