| Tweet |

Custom Search

|

|

|

||

3500 ENGINES

DISASSEMBLY AND ASSEMBLY

OIL PUMP

ASSEMBLE OIL PUMP

1304-16

Tools Needed

A

1P510

Driver Group

1

1.

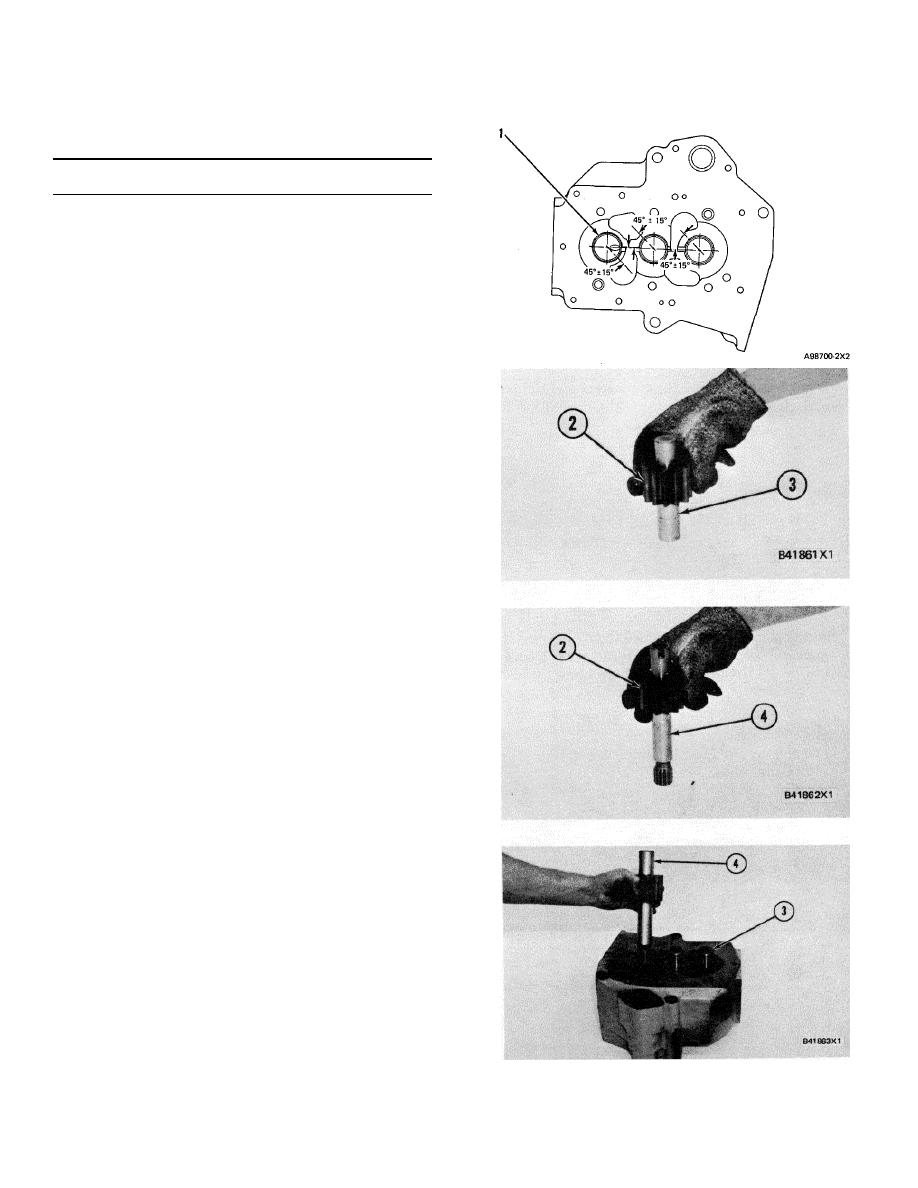

Make an alignment of bearings (1) so the joints

are 45 15 from a line through the center of the

O

bearing bores as shown.

2.

Use tooling (A) to install bearings (1) in the body

assembly until they are 1.5 0.5 mm (.059 .020

in.) below the gear bore in the body assembly.

Check the inside diameter of the bearings after

installation. The diameter must be 31.837

0.070 mm (1.2534 .0028 in.).

3.

Heat gears (2) to a maximum temperature of

O

O

316 C (600 F).

4.

Install the gears on shaft assemblies (3) until

they are 34.0 0.5 mm (1.34 .020 in.) from the

cover end of the shaft assemblies to the face of

the gears and 47.0 0.5 mm (1.85 .020 in.)

from the fuel pump drive end of shaft assembly

(4).

5.

Install shaft assemblies (3) and (4) in the body

assembly.

291

|

||

|

||