| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

(2) Select a new plunger and coat with Prussian bluing.

CAUTION

DO NOT ALTER SIZE OF INJECTOR CUP SPRAY HOLES.

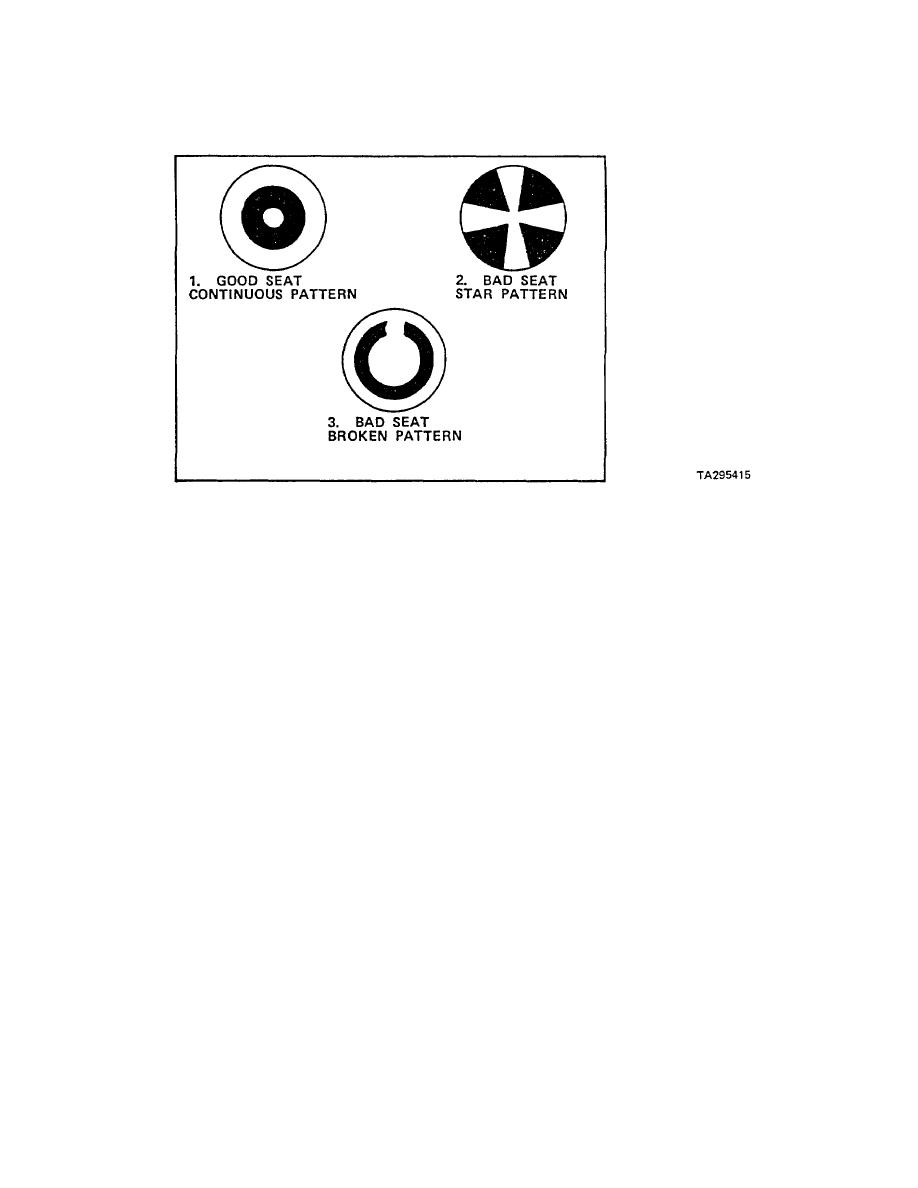

(3) Insert plunger into cup and rotate plunger 90. If plunger seat covers a 40 percent continuous area around

cup cone it is possible to reuse cup if it passes cup-to-plunger leak test. Compare contact patterns to those

shown in above illustration.

(4) Check injector cup to barrel contact surface for distortion and flatness.

Use surface plate to check for

flatness. Replace cup if any defects noted.

c. Inspect injector barrel.

CAUTION

BARREL AND PLUNGER ARE MATCHED SETS AND MUST BE REPLACED AS AN

ASSEMBLY TO ENSURE PROPER OPERATION OF INJECTOR.

(1) Inspect barrel plunger bore for scoring. If injector passes leakage test after reassembly, barrel is useable.

(2) Using illuminated magnifier, check for burrs, carbon, and distorted radii in orifice.

3-265

|

||

|

||