TM 9--2815--247--34

0069 00--1

PISTONS, RINGS, AND ASSOCIATED PARTS REPAIR

0069 00

THIS WORK PACKAGE COVERS:

Disassembly, Cleaning, Inspection, Repair, Assembly

INITIAL SETUP:

Tools and Special Tools

General mechanic’s tool kit (item 19, WP 0103 00)

Ring remover and replacer (item 37, WP 0103 00)

Plain ring gauge: standard and 0.020 oversize

(item 17, WP 0103 00)

Outside micrometer caliper set (item 9, WP 0103 00)

Inside micrometer caliper set (item 10, WP 0103 00)

Telescoping gauge set (item 16, WP 0103 00)

Magnifying glass (item 24, WP 0103 00)

Zyglo penetrant kit (item 76, WP 0103 00)

Materials/Parts

Carbon--removing compound (item 3, WP 0100 00)

Dry--cleaning solvent (item 5, WP 0100 00)

Abrasive cloth (item 4, WP 0100 00)

Safety goggles (item 28, WP 0100 00)

Equipment Conditions

Engine on maintenance stand (WP 0056 00)

Cylinder head assembly and piston removed (WP

0059 00)

NOTE

The engine has 12 pistons and the following procedures

will apply to one or all pistons.

Disassembly

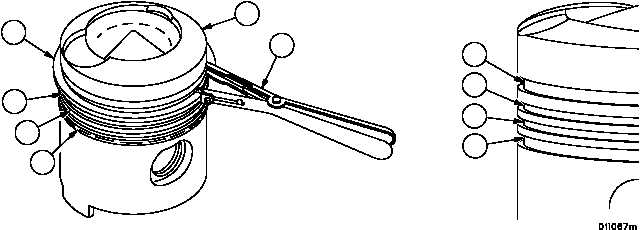

1. Check to see if compression rings (1, 2, and 3) and oil control ring (4) are free in piston grooves before removal.

2. Mark ring grooves (5, 6, 7, or 8) for any sticking rings for further detailed inspection.

3. Place jaws of remover and replacer (9) in the end gap of upper piston ring (1), spread ring, lift out of groove and

remove from piston (10).

4. Mark ring (1) for identification showing piston number and groove location.

5. Remove two intermediate compression rings (2 and 3) and oil control ring (4) in the same manner.

6. Mark rings (2, 3, and 4) for identification showing piston number and groove location.

Figure 8

1

2

3

4

5

6

7

8

9

10

|

|