| Tweet |

Custom Search

|

|

|

||

TM 9-8000

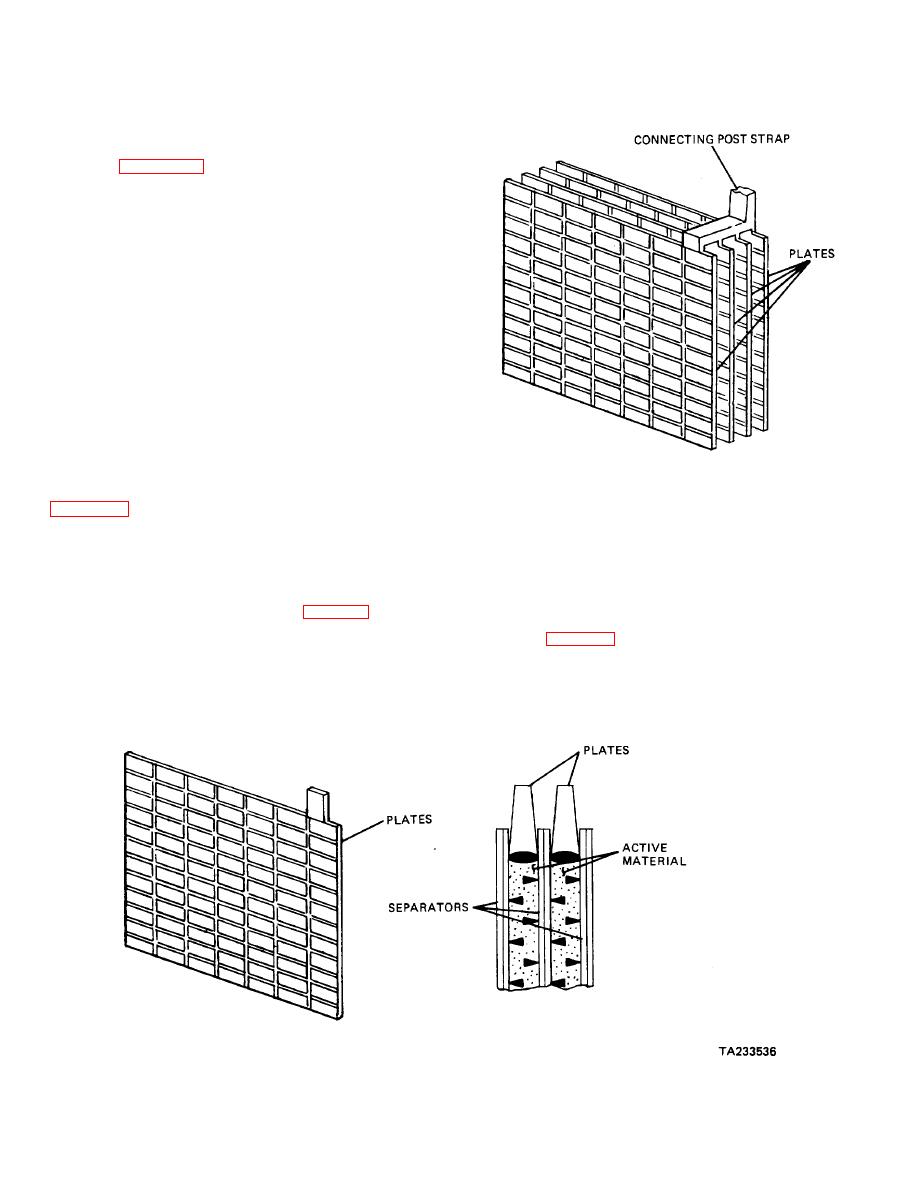

lead oxides, is applied to the grids in paste form, then

allowed to dry and harden like cement. Part of a grid is

shown in figure 12-2 with a cross section showing the

active material in place. The plates are then put through

an electrochemical process that converts the hardened

active material of the positive plates into brown lead

peroxide, and that of the negative plates into gray,

spongy, metallic lead. This process is known as forming

the plates.

b. Groups. After the plates have been formed,

they are built into positive and negative groups. The

plates of each group are permanently joined by melting a

portion of the lug on each plate to form a solid weld with

a connecting post strap. The heat necessary for this

process, termed lead burning, is produced by a gas

flame or an electric arc. The connecting post strap to

which the plate lugs are burned contains a cylindrical

terminal that forms the outside connection for the cell.

The negative group of plates has one more plate than

Figure 12-3. Cell Group Construction.

the positive group to provide a negative plate on both

sides of all positive plates. These groups are shown in

against the positive plate) is grooved so the gas that

forms during charging will rise to the surface more

readily. These grooves also provide room for any

c. Separators. To prevent the plates from touching

material that flakes from the plates to drop to the

and causing a short circuit, sheets of insulating material

sediment space below.

(microporous rubber, fibrous glass, or plastic-

impregnated material), called separators, are inserted

d. Elements. The assembly of a positive and

between the plates. These separators (fig. 12-4) are thin

negative group, together with the separators, is called an

and porous so the electrolyte will flow easily between the

element (fig. 12-4). Because storage battery plates are

plates. One side of the separator (that is placed

more or less of standard size, the number of plates in an

element is, roughly, a measure of the battery capacity.

The distance between the plates of an assembled

element

is,

approximately

one-eighth

inch.

Figure 12-2. Plate Construction.

12-2

|

||

|

||