| Tweet |

Custom Search

|

|

|

||

TM 9-8000

and the plane in which the balls lie will be reduced to 80

remaining in a plane that bisects the angle between the

degrees, fulfilling the requirement that the balls must lie

two shafts. The fork ends subtend an angle greater than

In the plane that bisects the angle of drive.

180 degrees so as to be self-locking once the joint is

assembled to the inner parts of the joint. A flat surface is

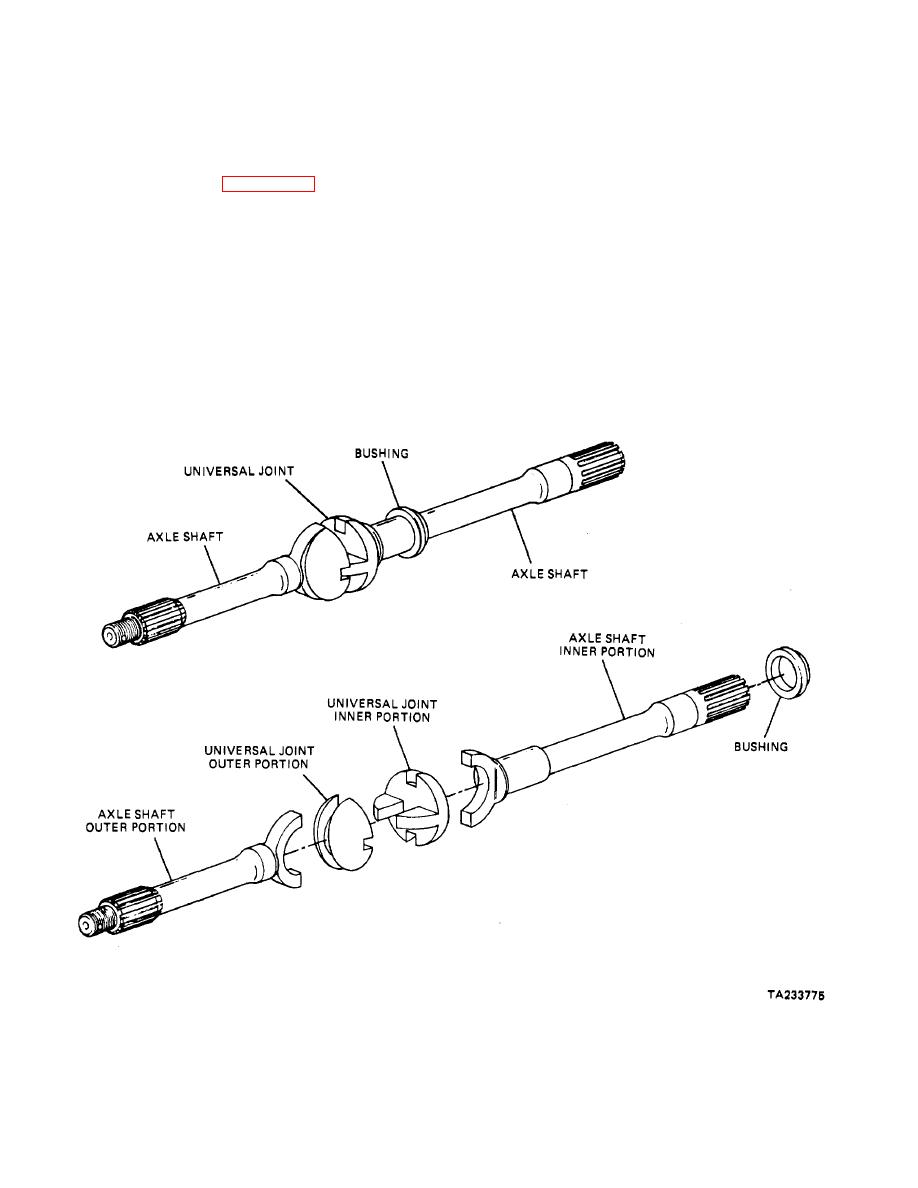

c. Tracta Joint (Fig.

milled on the cylindrical section of the joint to permit the

The

Tracta

Joint to be Inserted in place.

universal joint is the simplest to Install and service. It is,

in effect, one universal joint within another, with points of

d. Double Cross and Roller (Flg. 28-8). The

driving contact on the outer portions of the Joint. This

double cross and roller Joint uses two cross and roller

universal Joint consists of four main parts: a forked

Joints in tandem to form a single joint. The joints are

driving shaft, a forked driven shaft, a female (or slotted)

linked through a centering yoke that works In conjunction

Joint, and a male (or spigot) Joint. The complete Inner

with specially designed, spring-loaded centering ball.

Joint, consisting of the female Joint and the male Joint,

The components are contained within the center

floats between the forks; movement between the

coupling yoke. As the shaft rotates, the action of the

Individual halves of the Inner Joint is permitted In a

centering ball and yoke act to maintain an equally divided

direction perpendicular to that permitted by the slotted

drive angle between the connected shafts, resulting In a

forks, by the action of the spigot moving In the slot. With

constant drive velocity.

this arrangement, the points of driving contact are

allowed to move as the universal joint rotates, thereby

Figure 28-7. Tracta Constant Velocity Joint.

28-8

|

||

|

||