| Tweet |

Custom Search

|

|

|

||

TM 9-8000

poor riding qualities, thereby limiting vehicle mobility.

The suspension springs are shackled at both ends.

However, this drive system is in extensive use because

In a torque tube drive, both the torque reaction and the

of simplicity, low cost, and ruggedness.

driving thrust are resisted by the torque tube. Because

the suspension springs do not resist the torque reaction

An advantage of the Hotchkiss drive is that the flexible

and drive thrust, they can be made more flexible and

connection between axle and frame throws less strain on

give better riding qualities than a Hotchkiss drive.

the driving mechanism than do other types. When

sudden loads are applied, as in suddenly engaging the

In a torque tube drive, the driving thrust is applied to the

clutch, the axle housing can rock around the drive shaft

frame at the engine mounting or at a frame

slightly, which cushions the shock transmitted through

crossmember. In a torque rod or Hotchkiss drive, the

the driving mechanism and reduces the load between

force is applied at the suspension springs. The torque

the teeth of the final driving mechanism.

tube drive seldom is used in contemporary designs.

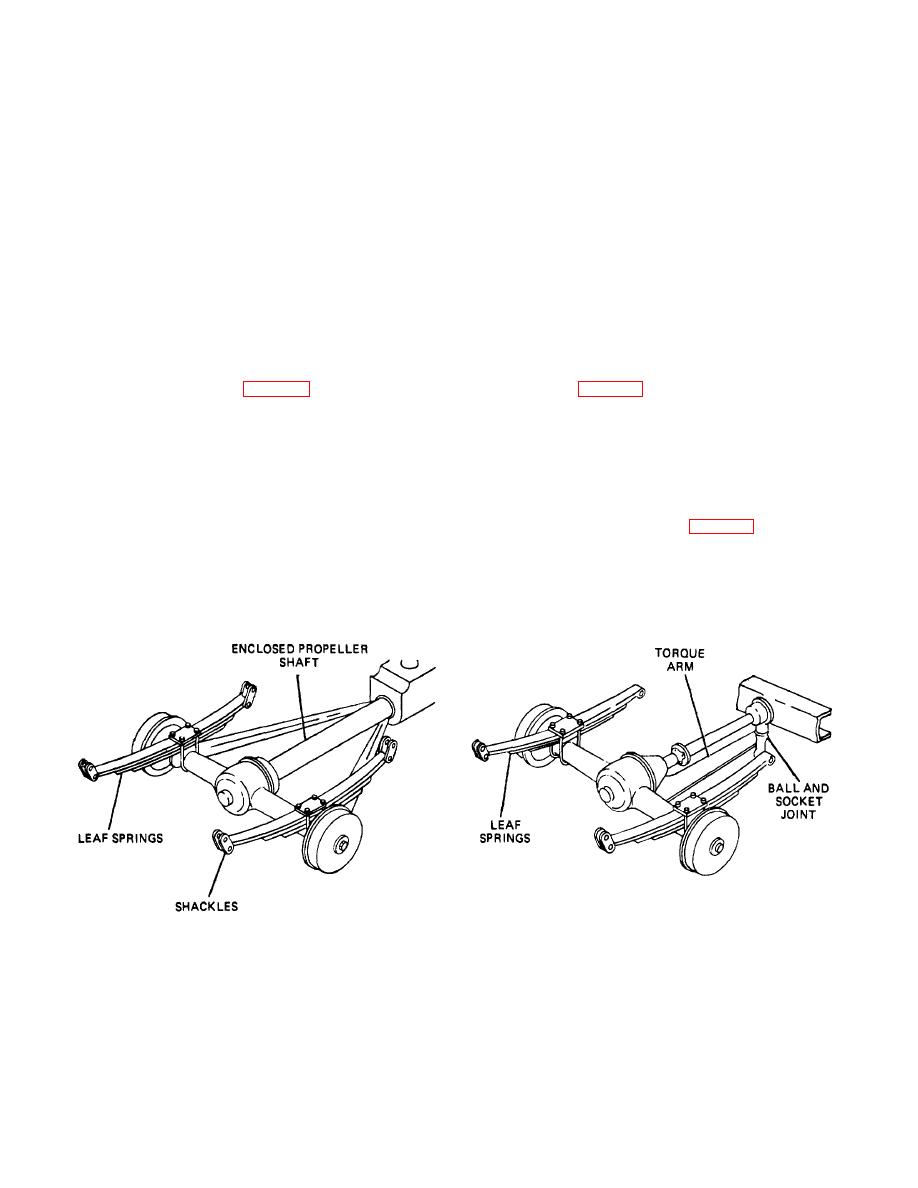

b. The torque tube drive, while not common on

c. The torque arm drive rarely is used. It consists

heavy military vehicles, is used on a limited number of

of a solid or tubular arm, rigidly connected to the driving

passenger and light commercial vehicles. In this type of

axle housing at its rear end and to a frame crossmem-

drive, the propeller shaft (drive shaft) is housed in a steel

ber, through a ball-and-socket Joint or spring bracket, at

tube called the torque tube (fig. 30-5). The rear end of

its front end (fig. 30-6). An open propeller shaft is used

the torque tube is bolted rigidly to the rear axle housing

on a torque arm drive. The torque arm drive is similar to

by means of a flange. Its front end is connected to the

the torque tube drive. The main difference is that it uses

transmission or a frame crossmember by means of a

an open propeller shaft running parallel to the torque

ball-and-socket joint. One universal Joint is used in the

arm, instead of a drive shaft housed within a torque tube.

propeller shaft and is located at the ball-and-socket Joint

d. Coil Spring and Control Rod Drive. This type of

of the torque tube. A slip Joint is placed in the propeller

shaft to take up end play arising when the driven axle

live axle suspension commonly is used in modern

moves up and down. A center bearing generally is used

vehicles. In this configuration (fig. 30-7), the coil springs

to support the drive shaft in the torque tube.

are placed between the axle housing and the frame.

Their sole purpose is to support the weight of the vehicle.

Two suspension system radius rods are used to connect

All torque reaction due to accelerating and braking and

the outboard ends of the axle housing with the

all

transmission end of the torque tube. This will keep the

axle housing alined at right angles to the torque tube.

Figure 30-5. Torque Tube Drive.

Figure 30-6. Torque Arm Drive.

TA233802

30-4

|

||

|

||