| Tweet |

Custom Search

|

|

|

||

3500 ENGINE

SPECIFICATIONS

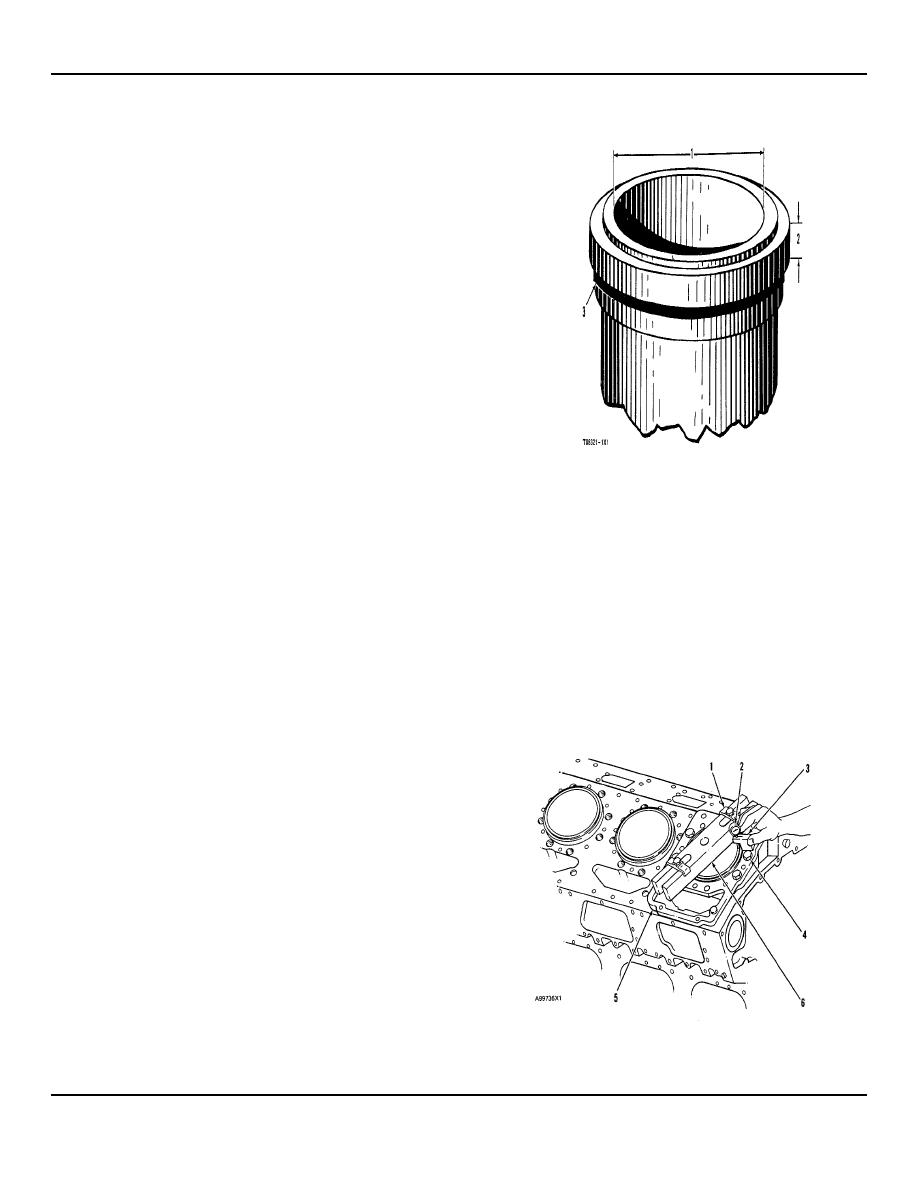

CYLINDER LINERS

For Installation

a. Put liquid soap on cylinder block liner bore

surfaces and rubber seals on the lower part

of the liner.

b.

Put the filler band completely in clean

engine oil for a moment.

c.

Install filler band (3) in the groove under the

liner flange, without delay.

d.

Install the liner in the bore immediately,

before expansion of the filler band.

(1)

Bore in liner

(new)....................... 170.0250.025

mm

(6

6939 0010 in.)

(2)

Thickness of flange

on liner............ 12.65 0.02 mm (.498 001 in )

(3)

Filler Band.

CYLINDER LINER PROJECTION

liner must be.......................... 0.059 to 0

199 mm (.0023 to .0078 in.)

Make reference to CYLINDER LINER PROJECTION in

Testing and Adjusting for the complete procedure.

Maximum permissible difference between

all four measurements .......... 0.05

mm

1.

Install the gasket and spacer plate (5).

(.002 in.)

Install copper washers and bolts (4) to hold

the spacer plate Tighten bolts (4) evenly in

(1)

3H465 Plate

four steps.

1st step .................. 14 Nm (10 lb. ft.)

(6)

8B7548 Push-Puller Crossbar.

2nd step ................. 35 Nm (25 lb. ft )

3rd step................... 70 Nm (50 lb. ft )

4th step ................... 95 Nm (70 lb. ft )

2.

Install tooling as shown. Tighten bolts for

crossbar evenly in four steps.

1st step .....................

7 Nm (5 lb ft.)

2nd step .......................

20 Nm (15 lb ft )

3rd step.......................... 35 Nm (25 lb ft.)

4th step ........................ 70 Nm (50 lb ft.)

3. Measure cylinder liner projection with dial

indicator (2) in 1P2402 Gauge Body (3) as

shown Measure at four places around each

cylinder liner near the clamped area

Average of four projection measurements

from

any

cylinder

NOTE: FOR TORQUE VALUES NOT GIVEN, SEE THE FIRST35 PAGE OF SPECIFICATIONS FOR

GENERAL TIGHTENING TORQUES

35

|

||

|

||