| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

SYSTEMS OPERATION

Governor accumulator oil pressure is changed to

a restricted variable (pulsating) oil flow as small holes

(ports) in the pilot valve bushing move past a passage in

the controlet housing. In a constant speed opera- tion,

the ball valve is not tight against its seat and lets oil flow

back to the sump. The ball valve is held in position by

the sensing bellows, which is connected to inlet manifold

air pressure. The force used to hold the ball valve is

proportional to the inlet manifold air pressure.

As inlet manifold air pressure increases, the ball

valve makes contact with its seat and oil pressure

increases to move the limiter piston to the right against

the force of the restoring spring. This movement

increases the tension on the restoring spring until the

spring force is in balance with the sensing bellows force.

The oil pressure now can push the ball valve off its seat

and let a small amount of oil flow to the sump. This

reduces the pressure behind the limiter piston and the

piston stops movement.

The piston position is

UG8 LEVER GOVERNOR

proportional to inlet manifold air pressure.

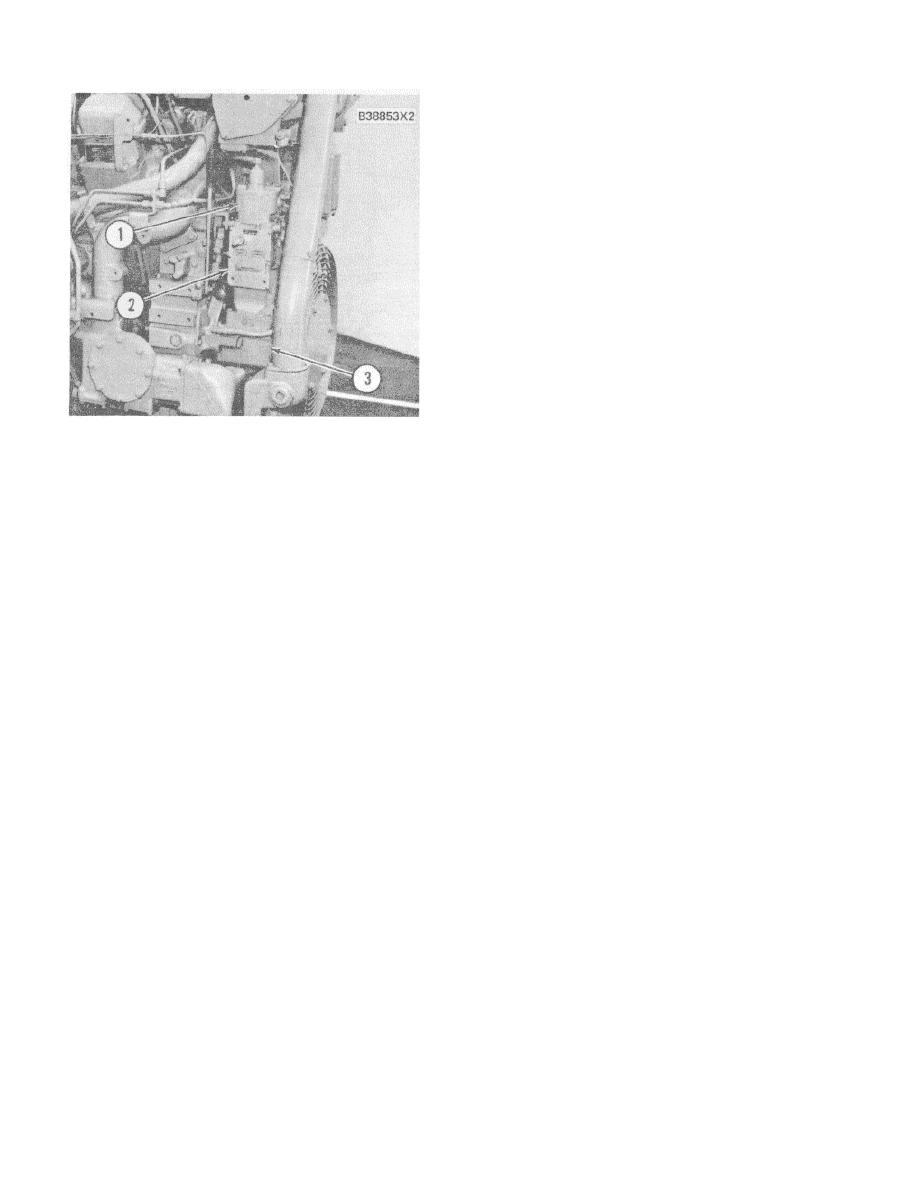

1. Air-Fuel ratio control. 2. Governor. 3. Governor

drive.

The cam fastened to the limiter piston operates

AIR FUEL RATIO CONTROL

through linkage to limit the travel of the governor terminal

shaft. The governor terminal shaft limits the fuel to the

The air fuel ratio control is installed on top of the basic

engine through the fuel control link- age. The terminal

UG8L Governor. The unit is made up of an inlet

shaft can turn in the increase fuel direction until the pivot

manifold pressure sensor, a hydraulic circuit and

lever lifts the pilot valve above center. Oil pressure on

mechanical linkage that connects the unit to the

the bottom of the power piston is now directed to the

governor. Pressure oil from the governor hydraulic

sump. The power piston moves down and causes the

system is used to operate the unit.

terminal shaft to turn in the decrease fuel direction.

When engine speed or load is increased rapidly, it is

When the engine is stopped, the limiter piston is

possible for a standard (unlimited) governor to supply

held to the left by the restoring spring. The fuel limit

more fuel than can be burned with the amount of

valve at this position is set high enough by the cam to

available air. Too much smoke and poor acceleration

give enough fuel for start up. At cranking speed, oil

are the result. The fuel ratio control works to limit the

pressure behind the limiter piston goes by the diaphram

movement of the governor terminal shaft in the increase

to the sump. After the engine has started, engine

fuel direction as a direct result of inlet manifold pressure.

lubrication oil pressure pushes the diaphram against its

Thus, fuel which can be burned is limited to the air

seat and closes the governor oil drain. Oil pressure now

available for combustion as the engine speed is

increases behind the limiter piston. The limiter piston

increased. This gives more complete combustion and

moves out until the roller follower is on the operating

keeps smoke to a minimum while acceleration is

slope of the cam. At this point the ball valve is moved off

improved.

its seat, the oil can now flow to sump and the piston

movement is stopped.

The air fuel ratio is also used for protection to limit the

fuel as the result of any large, sudden restriction of air

supply to the engine.

73

|

||

|

||