| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

TESTING AND ADJUSTING

3.

If leakdown time for the first test is one minute or

more, the leakdown time is acceptable and no

additional leakdown tests are necessary.

4.

If leakdown time for the first test is less than one

minute, it will be necessary to make three

additional leakdown tests. Get an average of the

results of the three additional tests.

5.

If the average leakdown time of an injector is

less than the time given in the specifications

shown, do not use the injector. A repair or

replacement of the injector must be made.

If there is to be a repair of the injector, see

REPAIR OF UNIT INJECTORS in Special Instruction,

Form No. SEHS8190.

FUEL PRESSURE

The 6V3150 Engine Pressure Group can be

used to check engine fuel pressures.

FUEL MANIFOLD AND LINES

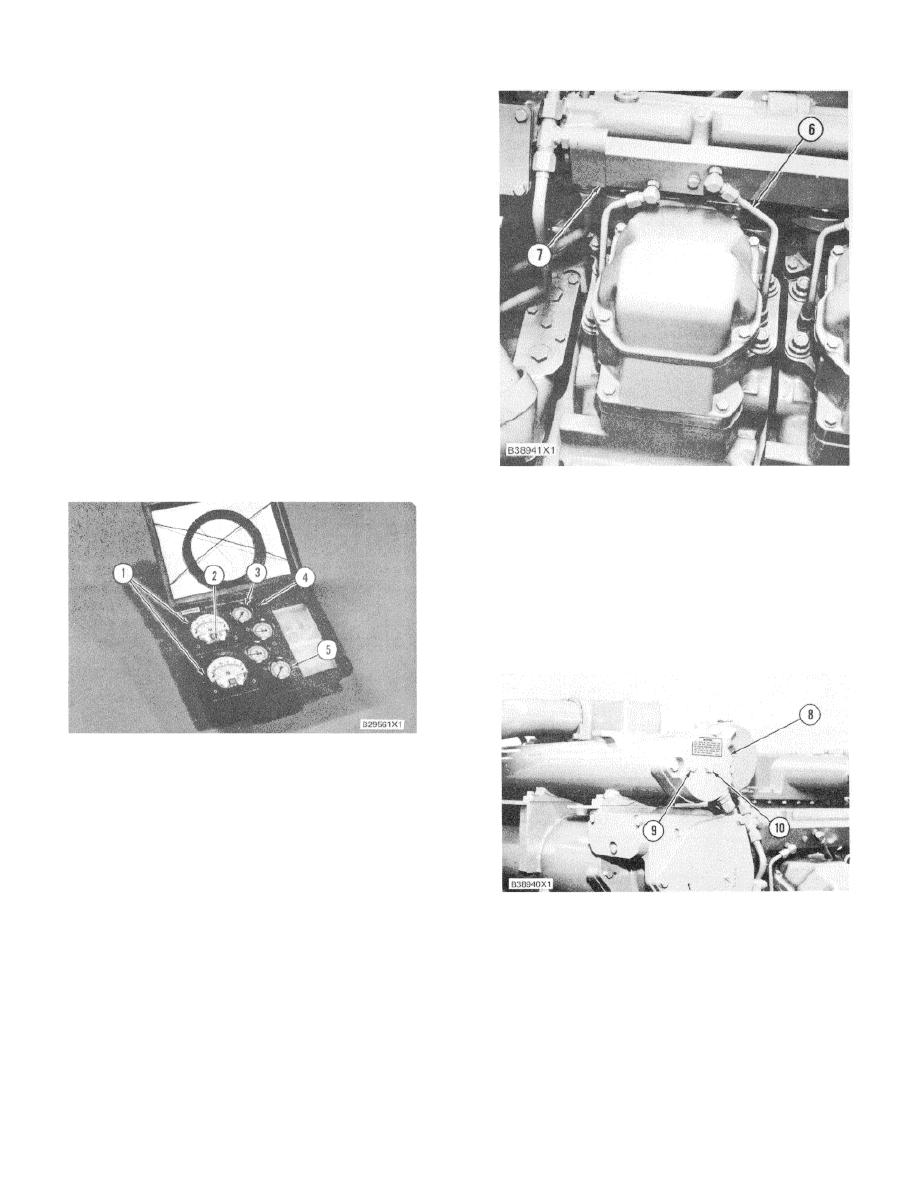

6. Fuel supply line to cylinder head. 7, Fuel manifold.

The fuel pressure regulating valve keeps the

pressure in fuel manifolds (7) between 415 and 450 kPa

(60 to 65 psi). To check the fuel manifold pressure,

disconnect one of the fuel lines (6) and install a tee

between the line and manifold. Connect the 6V3150

Engine Pressure Group to the tee and operate the

engine.

6V3150 ENGINE PRESSURE GROUP

1. Differential pressure gauges. 2. Zero adjustment

screw. 3. Pressure gauge 0 to 1100 kPa (0 to 160 psi).

4. Pressure tap. 5. Pressure gauge 0 to 415 kPa (0 to

60 psi).

This tool group has a gauge to read pressure in

the fuel manifolds.

Special Instruction Form No.

SEHS7851 is with the tool group and gives information

for its use.

FUEL TRANSFER AND FILTER DIFFERENTIAL

PRESSURES

8. Fuel filter housing. Plug. 10. Plug.

The outlet pressure of the fuel transfer pump can

be checked at the location of plug (10) in filter housing

(8).

Also the fuel filter differential can be checked at

plugs (9) and (10) in filter housing (8).

116

|

||

|

||