| Tweet |

Custom Search

|

|

|

||

FUEL SYSTEM

TESTING AND ADJUSTING

ENGINE ROTATION

SAE standard engine crankshaft rotation is

counterclockwise as seen from the flywheel end of the

engine.

FINDING TOP CENTER POSITION FOR NO. 1

PISTON

Tools Needed:

9S9082 Engine Turning Tool.

TIMING BOLT INSTALLATION

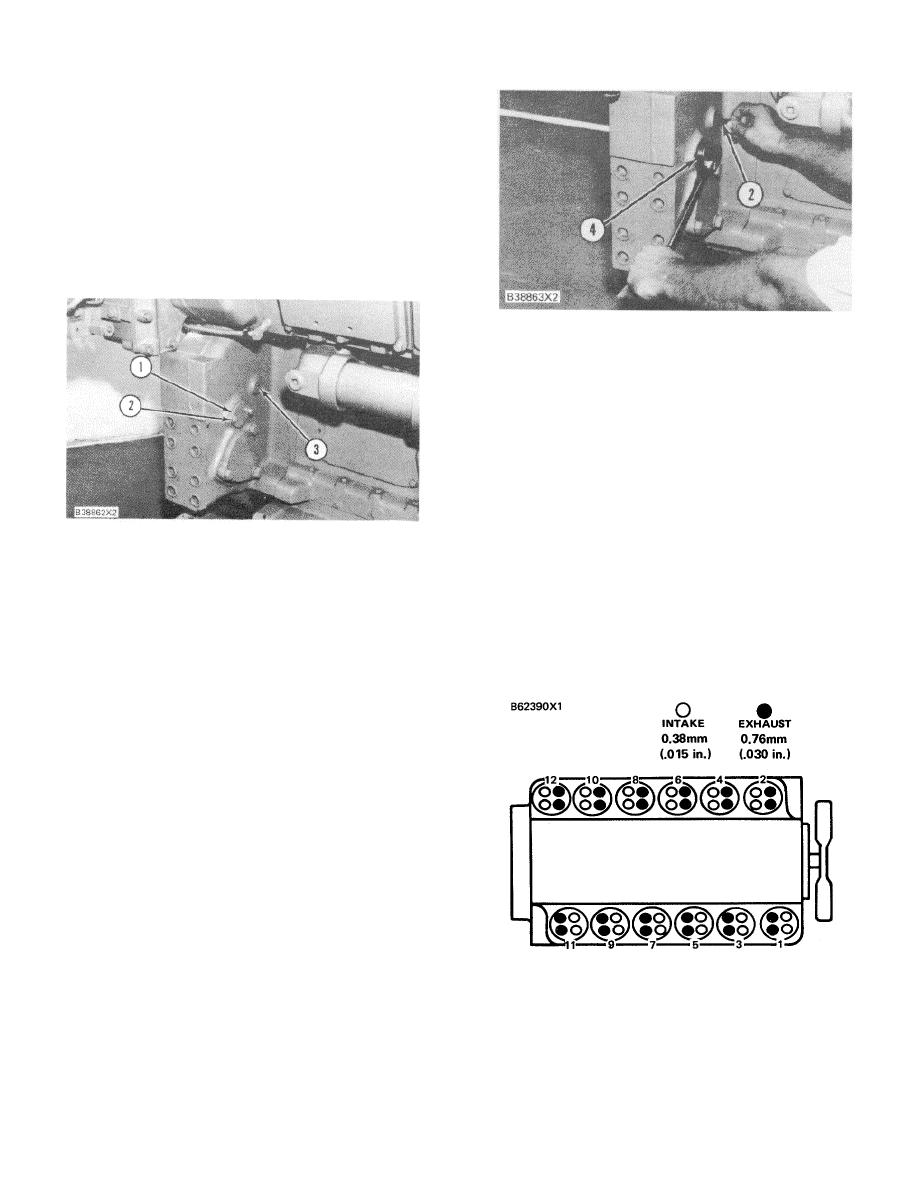

2. Timing bolt. 4. 9S9082 Engine Turning Tool.

4.

The intake and exhaust valves for the No. 1

cylinder are fully closed if No. 1 piston is on the

compression stroke and the rocker arms can be

moved by hand. If the rocker arms can not be

moved and the valves are slightly open, the No.

1 piston is on the exhaust stroke.

Make

reference to charts for CRANKSHAFT

POSITIONS FOR INJECTOR TIMING AND

VALVE CLEARANCE SETTING to find the

correct cylinder(s) to be checked/adjusted for the

TIMING BOLT LOCATION

stroke position of the crankshaft when the timing

1. Cover. 2. Timing bolt. 3. Timing bolt hole In

bolt has been installed in the flywheel.

flywheel housing.

NOTE: When the actual stroke position is identified, and

1.

Remove cover (1) and the timing hole plug from

the other stroke position is needed, it is necessary to

the right front side of the flywheel housing. On

remove the timing bolt from the flywheel and turn the

some engines there is a cover and timing bolt

flywheel 3600 in the direction of normal engine rotation.

hole located on the left side, also.

2.

Put timing bolt (2) [long bolt that holds cover (1)

on the flywheel housing] through the timing hole

in the flywheel housing. Use the 9S9082 Engine

Turning Tool (4) and 1/2" drive ratchet wrench to

turn the engine flywheel in the direction of

normal engine rotation until the timing bolt

engages with the threaded hole in the flywheel.

NOTE: If the flywheel is turned beyond the point that the

timing bolt engages in the threaded hole, the flywheel

must be turned opposite normal engine rotation

approximately 30 degrees. Then turn the flywheel in the

direction of normal engine rotation until the timing bolt

engages with the threaded hole. The reason for this

procedure is to make sure the play is removed from the

gears when the No. 1 piston is put on top center.

CYLINDER AND VALVE LOCATION

(3512 SHOWN)

3.

Remove the valve cover for the No. I cylinder

head.

117

|

||

|

||