| Tweet |

Custom Search

|

|

|

||

AIR INLET AND EXHAUST SYSTEM

TESTING AND ADJUSTING

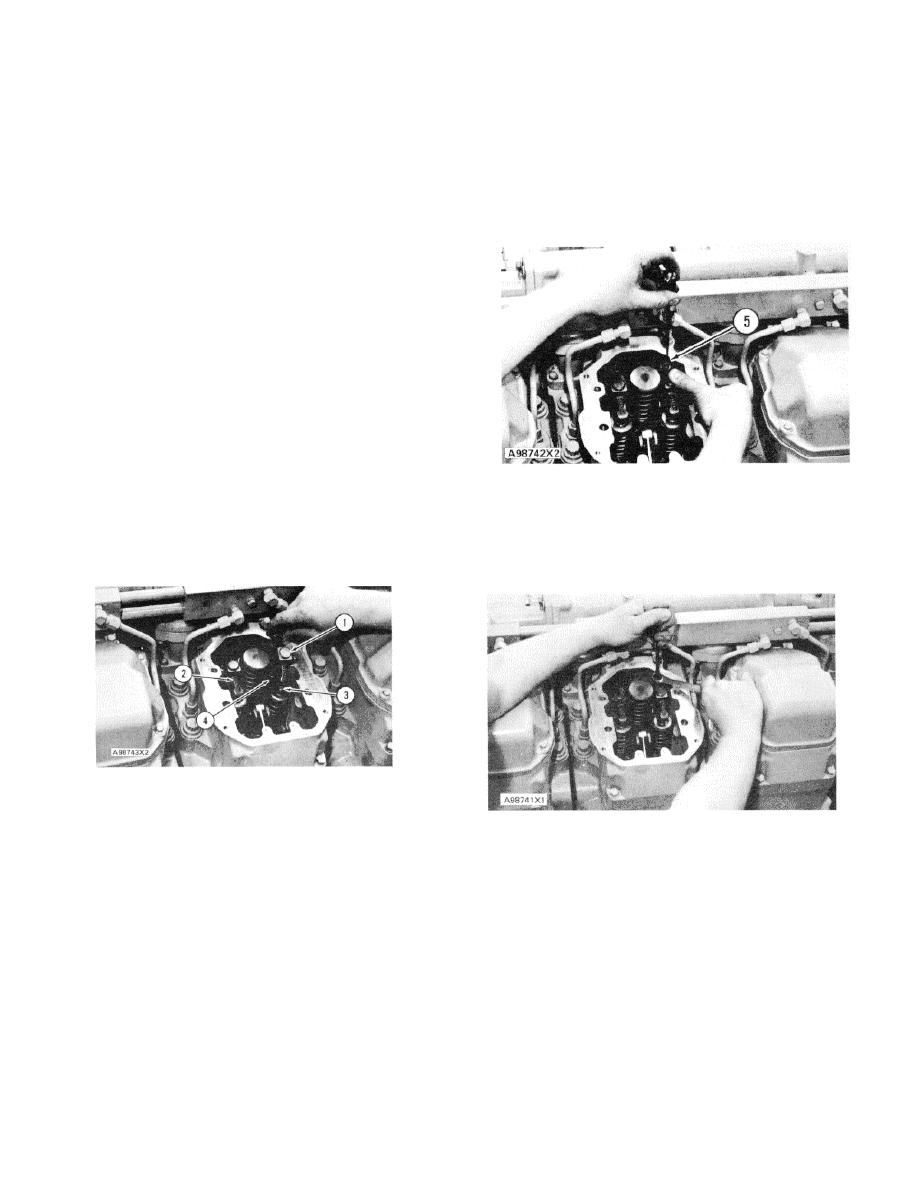

Bridge Dowels

5.

Turn adjustment screw (5) clockwise until it just

makes contact with valve stem (3). Then turn

Use a 5P944 Dowel Puller Group with a 5P942

the adjustment screw 20 to 300 more in a

Extractor to remove the bridge dowels. Install a new

clockwise direction to make the bridge straight

bridge dowel with a 6V4009 Dowel Driver. This dowel

on the dowel, and to make compensation for the

driver installs the bridge dowel to the correct height.

clearance in the threads of the adjustment

screw.

BRIDGE ADJUSTMENT

When the cylinder head is disassembled, keep

the bridges with their respective valves. To make an

adjustment to the bridges, use the procedure that

follows:

NOTE: The only time bridge adjustment is necessary is

when a valve has been replaced, ground, or cylinder

head has been reconditioned. Valves must be fully

closed when adjustment is made. To find when valves

are fully closed, see subject FINDING TOP CENTER

POSITION FOR NO.

1 PISTON and chart

CRANKSHAFT POSITIONS FOR INJECTOR TIMING

AND VALVE CLEARANCE SETTING.

BRIDGE ADJUSTMENT

1.

Put engine oil on bridge dowel (4) in the cylinder

5. Adjustment screw.

head and in the bore in bridge (2).

6.

Hold adjustment screw (5) in this position and

2.

Install bridge (2) with adjustment screw (5)

tighten the locknut to 30 4 Nm (22 3 lb. ft.).

toward the exhaust manifold.

BRIDGE INSTALLATION

1. Top contact surface. 2. Bridge. 3. Valve stem. 4.

Bridge dowel.

TIGHTEN LOCKNUT

3.

Loosen the locknut for adjustment screw (5) and

loosen the adjustment screw several turns.

7.

Put engine oil on top contact surface (I) where

the rocker arm makes contact with the bridge.

4.

Put a force of 5 to 45 N (I to 10 lb.) by hand

straight down on top contact surface (I ) of

bridge (2).

135

|

||

|

||