| Tweet |

Custom Search

|

|

|

||

HYDRAMECHANICAL PROTECTIVE SYSTEM

SPECIFICATIONS

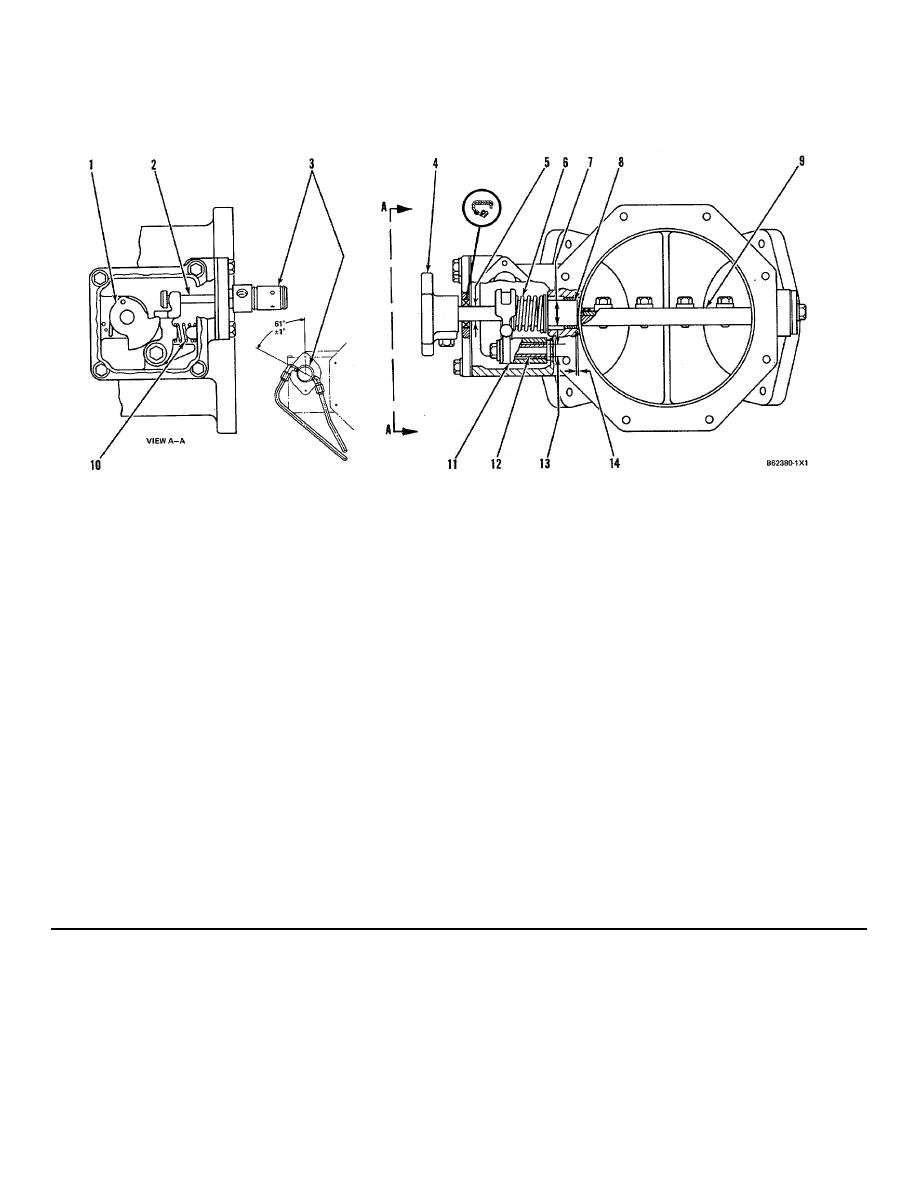

AIR INTAKE SHUTOFF

(2W5216)

bearings ....27.9970.010 mm (1.1230.0004 in.)

(1)

Latch.

(2)

Shutoff cylinder rod.

(8)

Shaft assembly.

(3)

Install shutoff cylinder as follows:

(9)

Plate assembly.

a. Assemble shutoff cylinder on the flange at

NOTE: With plate assembly (9) in the closed (shutoff)

the angle shown.

position, a 0.8 mm (.03 in.) feeler gauge must not pass

b. Tighten the nut that holds the shutoff

between the plate assembly and the housing bore at any

cylinder to the flange to a

position.

torque of ..................457 Nm (335 lb. ft.)

(10)

Lever return spring.

c. Install the flange on the air shutoff housing.

(11)

Lever.

Make sure cylinder rod (2) is engaged in

(12)

Sleeve.

the notch of lever (11).

(13)

Diameter of

sleeve..........14.9450.009 mm (.5995.0004 in.)

NOTE: The cylinder vent hole, between the ports, must

be in the downward position.

Bore in bushing (after

assembly)....15.0240.034 mm (.6026.0014 in.)

(4)

Knob.

(5)

Diameter of shaft assembly at

Bore in lever for

seal ..................... 15.880.05 mm (.625.002 in.)

bushing........17.0090.009 mm (.6823.0004 in.)

(6)

Air shutoff spring.

NOTE: Install both bushings to a dimension of 0.8 + 0.3

(7)

Diameter of shaft

mm (.03 + .01 in.) below the surface of lever ends.

assembly ............ 24.880.02 mm (.980.001 in.)

(14)

Dimension to install end of two bushings from

Bore in bushings for shaft assembly (after

machined

assembly) . 25.0170.040 mm (1.0035.0016 in.)

housing bore .........0.350.15 mm (.014.006 in.)

Bores in housing for

NOTE: FOR TORQUE VALUES NOT GIVEN, SEE THE FIRST

PAGE OF SPECIFICATIONS FOR GENERAL TIGHTENING TORQUES

208

|

||

|

||