| Tweet |

Custom Search

|

|

|

||

HYDRAMECHANICAL PROTECTIVE SYSTEM

SYSTEMS OPERATION

flyweights move out and push the speed sensing valve

Emergency Manual Shutoff

spool out to open and close passages to put oil pressure

into the correct system circuits. This gives correct

This shutoff is used under emergency conditions

protective system operation under the two engine oil

to shutdown the engine manually. When operated, this

pressure ranges.

shutoff simulates an engine overspeed condition in the

protective system.

Thus, the air and fuel to the

Diverter Valve

combustion chambers is stopped. The shutoff is also

used to check the protective system for correct operation

at regular engine maintenance periods.

If there is a low oil pressure, high coolant

temperature or engine overspeed condition, the diverter

The emergency manual shutoff can be operated

valve moves to put system oil pressure in the fuel shutoff

at the engine or from a remote location. For remote

circuit. This moves the governor and fuel control linkage

operation, either air or electric power can be used.

to the "SHUTOFF" position to shutdown the engine.

Shutoff Control Group

Thermostatic Pilot Valve

This valve is used to feel engine coolant

temperature. If the coolant temperature goes above the

limit of the thermostatic pilot valve, the valve opens and

causes engine shutdown through the fuel shutoff circuit

of the protective system.

Water Temperature Contactor

The contactor switch for water temperature is

installed in the water manifold housing (below the

regulator housing).

This is normally where the

thermostatic pilot valve is installed. No adjustment to the

temperature range of the contactor can be made. The

element feels the temperature of the coolant and then

operates a micro switch (in the contactor) when the

coolant temperature is too high. The element must be in

contact with the coolant to operate correctly. If the cause

for the engine being too hot is because of low coolant

level or no coolant, the contactor switch will not operate.

The switch is connected to an alarm system and

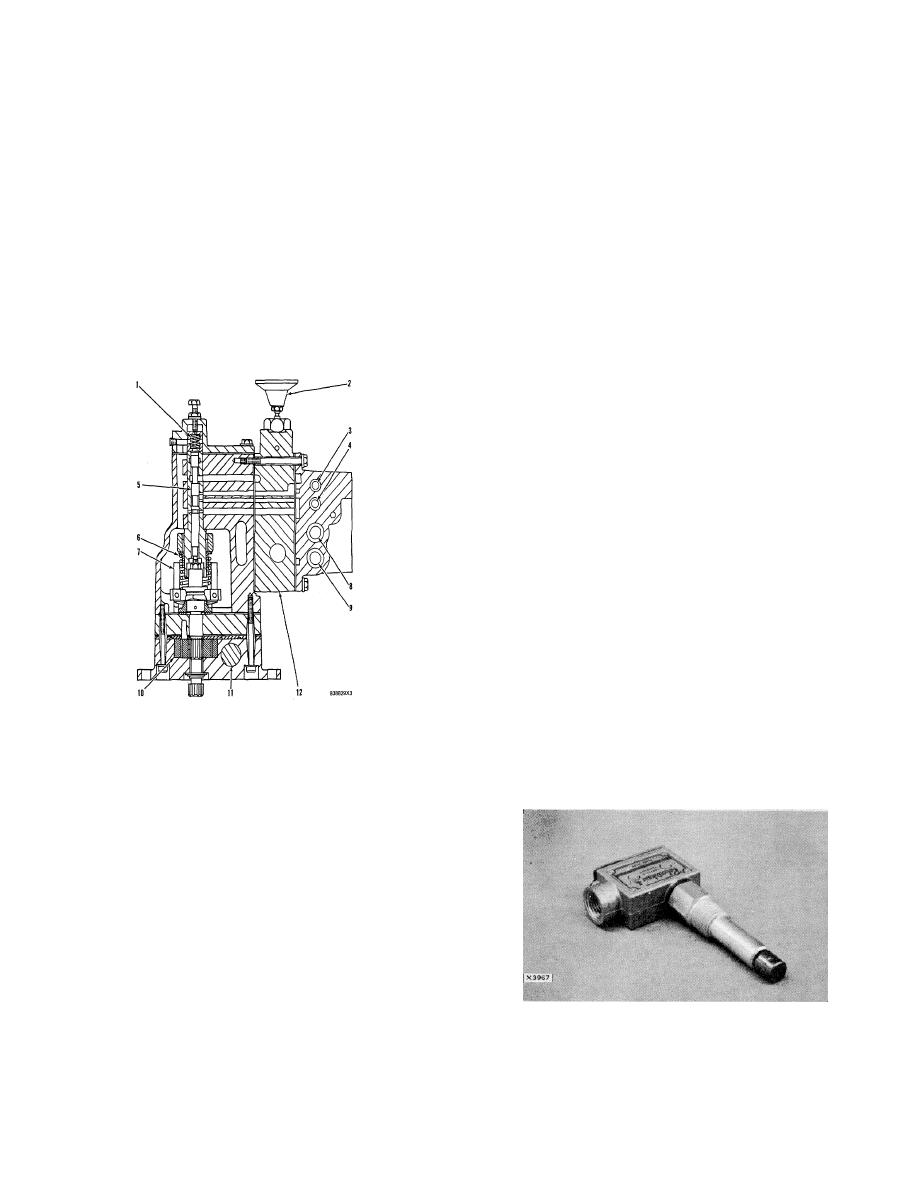

SHUTOFF CONTROL GROUP

activates an alarm under high coolant temperature

1. Spring for overspeed adjustment. 2. Emergency

conditions. When the temperature of the coolant lowers

manual shutoff valve. 3. Valve spool (not used). 4.

to the operating range, the contactor switch opens

Selector valve. 5. Speed sensing valve spool. 6.

automatically.

Speeder spring. 7. Flyweights. 8. Low speed oil

protection valve. 9. High speed oil protection valve.

10. Oil pump. 11. Oil pressure relief valve. 12.

Pressure control valve group which consists of: the

fuel and air inlet sequence valves, the two-way pilot

operated valve and emergency manual shutoff valve

(2).

A flyweight controlled, speed sensing valve spool is used

to feel engine speed. The speed sensing valve spool is

moved by flyweights which are turned by a drive shaft.

The drive shaft is driven by the engine camshaft through

an accessory drive group that has an oil reservoir for the

WATER TEMPERATURE CONTACTOR SWITCH

shutoff system. When engine speed increases, the

212

|

||

|

||