TM 5-2815-241-34&P

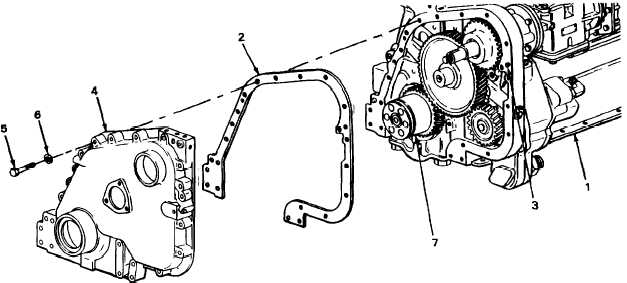

GEARCASE COVER INSTALLATION - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

NOTE

Method used for mounting dial indicator is at discretion of using facility. Position dial

indicator on crankshaft end face and set contact point of dial indicator on crankshaft

oil seal bore.

4. Cylinder block (1)

Crankshaft (7)

a.

Set dial indicator to zero.

b.

Using crankshaft barring tool, rotate

crankshaft and check dial indicator

reading for runout not to exceed 0.010

inch (0.25 mm).

5.

Gearcase cover (4)

Aline.

6. Gearcase cover (4)

Thirteen screws (5)

Using 1/2-inch drive 5/8-inch socket and

0 to 250 ft lb (0 to 350 N•m) torque wrench,

tighten to 45 to 50 ft lb (63 to 70 N•m).

T A 2 4 2 3 9 2

2-91

|

|