TM 5-2815-241-34&P

FLYWHEEL HOUSING INSTALLATION - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

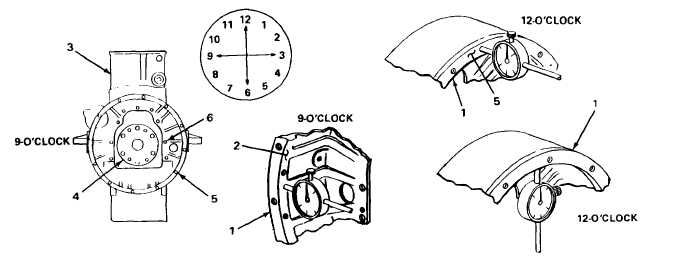

11.

Crankshaft (4)

Push forward to remove end clearance.

12.

Outer face (5)

a.

Set contact point of dial indicator on

outer face of flywheel housing and set

dial indicator to zero.

b.

Using crankshaft barring tool, rotate

crankshaft until dial indicator is at

6 o’clock position on flywheel housing.

c.

Note that reading on dial indicator does

not exceed 0.008 inch (0.20 mm).

If dial Indicator reading meets or is

below specification, perform step 13.

If dial indicator reading exceeds

specifications, tap flywheel housing

with inserted plastic-face hammer and

repeat steps 11 and 12.

13.

Nine screws (6)

Using 1/2-inch drive 15/16-inch socket,

6-inch extension, and 0 to 250 ft lb (0 to 350

N•m) torque wrench, tighten evenly to 150

ft lb (210 N•m).

T A 2 4 2 3 9 7

2-101

|

|