TM 5-2815-241-34&P

CYLINDER BLOCK - CONTINUED

I

ACTION

LOCATION

ITEM

REMARKS

REPAIR - CONTINUED

WARNING

Safety goggles must be worn to prevent eye injury caused by flying steel chips.

NOTE

Step 28 is for main bearing capscrew threads tagged for repairs and steps 29 thru 35 are

for cylinder block tagged for sleeve lower bore repairs.

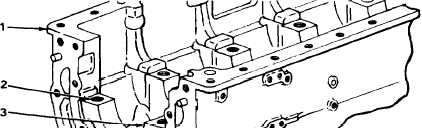

28. Cylinder block (1)

Main bearing

capscrew hole (2)

a.

Using 1/2-inch portable electric drill

and 1 1/32-inch bit, drill hole 2.675 to

2.705 inches (68.16 to 68.74 mm)

deep from main bearing cap pad (3).

b.

Using ST-1230 screw thread insert kit,

tap hole of 2.425 to 2.455 inches (61.60

to 62.36 mm) deep.

c.

Using inserting tool from kit, install

screw thread insert 0.860 to 0.890 inch

(21.84 to 22.61 mm) deep below main

bearing cap pad (3).

29. Cylinder block (1)

ST-1081 boring

tool (4)

Install assembled ST-1081 boring tool,

allowing bore adapter (5) to engage count-

erbore, and holes in adapter plate (6) to

match holes in cylinder block.

30.

Adapter plate (6)

a.

Fasten in place with capscrews (7).

b.

Using 1/2-inch drive, 1 1/16-inch socket,

and 0 to 150 ft lb (0 to 210 N•m)

torque wrench, screw in and torque cap-

screw 50 to 75 ft lb (6.9 to 10.4 kgm).

TA 242436

2-156

Change 1

|

|