TM 5-2815-241-3&P

CYLINDER BLOCK - CONTINUED

ACTION

LOCATION

ITEM

REMARKS

ASSEMBLY - CONTINUED

NOTE

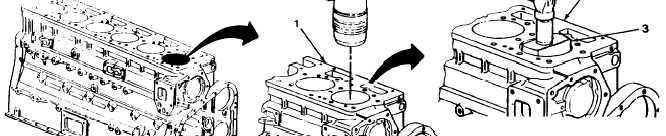

Lubricate machined portions of cylinder block, on which gasket, packing, and pre-

formed packing seat, with a light coat of clean lubricating oil.

68. Cylinder block (1)

Cylinder sleeve (2)

a.

Place in cylinder block.

Be careful not to dislodge gasket,

packing, and preformed packing.

b.

Press into position by hand.

c.

Using ST-1229 sleeve driver (3) and

16-ounce ball-peen hammer, drive

cylinder sleeve securely into cylinder

block so it fits squarely into cylinder

block bore.

d.

Install ST-1184 cylinder sleeve salvage

tool so foot of tool rests upon cylinder

sleeve fire ring.

e.

Using 0 - 150 ft lb (0 - 210 N•m)

torque wrench, tighten securing cap

screws to 50 ft lb (70 N•m) torque.

f.

Check cylinder sleeve protrusion. See

step 20.

g.

Check cylinder sleeve for out-of-round

condition. See step 22.

If cylinder sleeve is out of round,

remove and check for cause of

distortion.

TA 242446

2-170

|

|