*C2

PAR 137-141

T O R Q U E C O N V E R T E R H O U S I N G R E B U I LD

C H A P 5, SEC X V

S e c t i o n X V . T O R Q U E C O N V E R T E R H O U S I N G — R E B U I L D

1 3 7 . D E S C R I P T I ON

Refer to par. 9 for the description of the

torque converter housing.

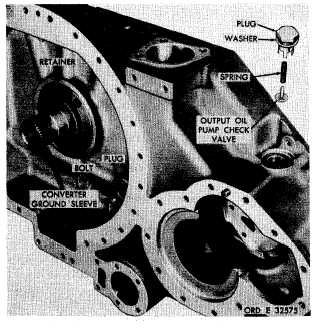

1 3 8 . D I S A S S E M B L Y ( f i g . 3 7 4 , f o l d - o u t 3 )

a . U s i n g a 1 - l / 2 - i n c h w r e n c h , r e m o ve

o u t p u t o i l p u m p c h e c k v a l v e p l u g , w a s h e r,

valve and spring (fig. 156).

b . U s i n g a 9 / 1 6 - i n c h w r e n c h , r e m o v e

five self-locking bolts retaining seal ring re-

t a i n e r ( f i g . 1 5 6 ) . R e m o v e t h e r e t a i n e r.

c . D o n o t r e m o v e t h e t o r q u e c o n v e r t er

g r o u n d s l e e v e u n l e s s r e p l a c e m e n t i s n e c e s-

sary (fig. 156). If necessary, press the sleeve

from the housing toward the front side.

d . R e m o v e a n y p l u g s i n t h e h o u s i n g if

necessary to aid in the cleaning of oil passages.

N o t e . I f n e c e s s a r y t o r e m o v e i n s e r ts

or dowels, refer to par. 72 for inspec-

tion and repair recommendations.

1 3 9 . C L E A N I NG

Refer to par. 71 for cleaning recommen-

d a t i o n s.

1 4 0 . I N S P E C T I O N A N D R E P A IR

R e f e r t o p a r . 7 2 f o r g e n e r a l i n s p e c t i on

a n d r e p a i r r e c o m m e n d a t i o n s . R e p a i r a n d r e -

b u i l d p o i n t s o f m e a s u r e m e n t f o r f i t s , c l e a r -

ances and wear limits are indicated by small,

lower

case

letters

in

fig.

374,

fold-out

3.

Refer to par. 237 for wear limits information.

Figure 156. Torque converter housing and related parts

1 4 1 . A S S E M B L Y ( f i g . 3 7 4 , f o l d - o u t 3)

a. Install any plugs in housing which were

removed to aid in the cleaning of the torque

converter housing (fig. 156).

b . I f t h e c o n v e r t e r g r o u n d s l e e v e w as

r e m o v e d , i n s t a l l a n e w r e p l a c e m e n t g r o u n d

s l e e v e ( f i g . 1 5 6 ) . P r e s s s l e e v e i n t o h o u s i ng

until firmly seated, being sure that the bolt

holes in the housing and sleeve are properly

indexed.

c . Install the seal ring retainer and secure

with five 3/8-16 self-locking bolts (fig. 156).

Torque the bolts to 36-43 pound-feet.

d . Install output oil pump valve, spring,

washer and plug (fig. 156).

1

21

|

|