TM 9-2520-272-34&P

4-15

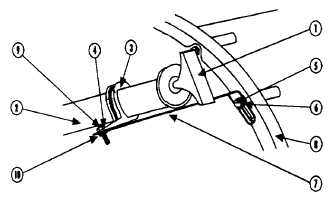

INSTALL OIL FILL TUBE ASSEMBLY

(SHEET 10 OF 11)

5 Coat o-ring (13) with transmission oil.

6 Install new o-ring (13) on elbow (11). Install o-

ring (13) until it seats on back up washer on

elbow (11).

7 Using your hands, in the direction of the bend in

the elbow (11), back off lock-nut (17), on the

elbow (11), as far as possible.

8 Inspect back up washer and o-ring (13) to insure

the back up washer is not loose and the o-ring

(13) and back up washer are pushed up, in the

direction of the bend in the elbow (11) as far as

possible.

9 Using your hands, screw elbow (11) and o-ring

(13) into the adapter (14) until the back up

washer makes contact with the adapter (14).

Light wrenching may be necessary to obtain

seating of the backup washer. If necessary use a

1-1/16 wrench for this purpose.

CAUTION:

For alignment of oil level tube assembly and

elbow, elbow is to be unscrewed by the required

amount. Do not align by turning elbow in a

10

To align the elbow (11) with the oil level tube

assembly (2), unscrew elbow (11) by the

required amount, but not by more than one full

turn. Light wrenching may be necessary to

obtain seating of the backup washer. If

necessary use a 1-1/16 wrench for this purpose.

NOTE:

Should repair not include installation of oil level

fill tube, position the elbow pointing towards

center of the LH Output Shaft. Using a 1-1/16

wrench to hold elbow and a 1-1/4 crowfoot and

torque wrench, torque nut on elbow to 79 87 lb

ft( 107118 N•m).

11 Using hands, install oil level fill tube (2) on elbow

(11).

12 Using a 1-1/16 wrench to hold elbow (11) and a

1-1/4 crowfoot and torque wrench, torque nut on

elbow to 79 87 lb ft(107 118 N•m).

Go to Sheet 3.

Para. 4-15, Task 4

Change 2 4-63.2

|

|