TM 9-2520-272-34&P

4-21.

ASSEMBLE RIGHT END COVER ASSEMBLY

(SHEET 22 OF 22)

5

X200-4 Using crowfoot and torque wrench, tighten

elbow (4) to 127 - 140 lb-ft (172 - 190 Nm) in the

position shown in illustration. (When oil line is

installed,

elbow

(4)

may

be

repositioned

to

accommodate oil line.)

6

Install output flange (5) in output shaft (6) located in

right end cover (3).

7

Install new tab washer (7) on 1/2-20 x 3-1/4 inch bolt

(8) with bent tab on washer toward head of bolt.

8

Install bolt (8) through center of flange (5) and into

center of output shaft (6). Install bolt finger tight.

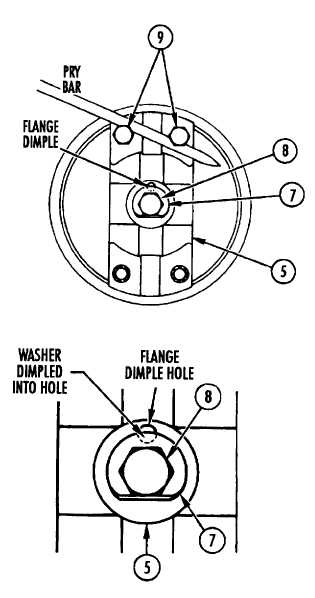

9

Using 3/4 inch socket, install two 1/2-20 x 3 inch

bolts (9) in tapped holes at either end of output

flange (5) until bolts are flush with inner surface of

flange.

10 Using one hand, hold pry bar between two bolts (9)

to prevent flange (5) from turning.

CAUTION

Do not install washer so that tab is over dimple in

flange. To prevent bolt from turning, tab must be

against flat of bolt and washer must be dimpled

into flange dimple hole. When tab of washer is

at dimple hole, washer cannot be dimpled. Bolt

retaining flange to output shaft may then loosen.

11 Using 3/4 inch socket and torque wrench, tighten bolt

(8) to 72-86 lb-ft (98-117 Nm).

12 Using 3/4 inch socket, remove two bolts (9) from

flange (5).

NOTE

Do not bend the tab of washer (7) against flat of bolt

(8) at this time.

13 Using punch and hammer, punch dimple in washer

(7). Dimple must depress washer into dimple hole in

flange (5).

FOLLOW-ON PROCEDURE: Install right end cover

assembly. Refer to paragraph 4-16.

End of Task 8

Para. 4-21, Task 8

Change 2 4-147

|

|