TM 9-2520-272-34&P

4-24. ASSEMBLE LEFT END COVER ASSEMBLY

(SHEET 4 OF 5)

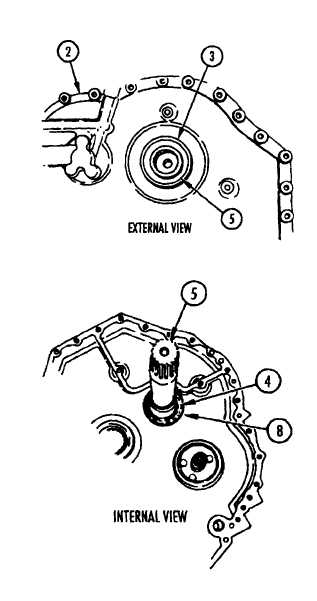

11

Carefully rotate shaft (5) and push end of shaft

through seal.

12

Keeping shaft very straight, use plastic faced

hammer on splined end of shaft (5) to seat

bearing (4) in shoulder on end cover (2). If

necessary, heat end cover with heat gun around

bearing journal if bearing does not easily seat.

13

Check that seal (3) remains in position in end

cover (2) and that lip on seal is not distorted

when shaft (5) passes through seal.

NOTE

When output shaft and bearing are

seated,

snapring

groove

will

be

accessible in sleeve at outer edge of

bearing.

14

Using screwdriver, install snapring (8) in groove

in sleeve above bearing (4).

15

Apply lubricating oil to bearing (4).

16

On X200-4A install new preformed packing (9)

on end of shaft (5).

17

Coat new packing with petrolatum.

End of Task 2

TASK 3. INSTALL LH OUTPUT FLANGE

COMMON TOOLS:

Bar, pry

Hammer, hand, machinist’s

Handle, socket wrench, 1/2 inch square drive

Punch, center, tapered point

Socket, socket wrench, 1/2 inch square drive,

3/4 inch

Wrench, torque, 0-175 ft-lb

REPAIR PARTS:

Washer, tab type (73342) 6752556

SUPPLIES:

Bolt, 1/2-20 x 3 inch (2 required)

Rag, wiping (Item 15, Appendix C)

Wooden Blocks, 2 x 4 inches x 16 inches long (2

required)

(Item 2, Appendix C)

Go to Sheet 5

4-158 Change 2

Para. 4-24, Task 2

|

|