TM 9-2815-202-34

4-12. FUEL PUMP REPLACEMENT (Cont)

c.

d.

Cleaning/inspection

(1) Clean all parts with fuel oil.

WARNiNG

Compressed air used for cleaning

purposes will not exceed 30 PSI.

Use only with effective chip

guarding and personal equipment

(goggles/shieid, gloves, etc.).

(2)

(3)

(4)

Dry all parts with compressed air.

Inspect drive gear and drive shaft for

scoring, burrs, or wear.

Inspect driven gear assembly for

scoring, burrs, or wear.

NOTE

Any slight damage on fuel pump body

and pump body cover sealing surfaces

may result in pressure leaks.

(5) Inspect fuel pump body and pump

body cover carefully for scratches,

nicks, or burrs.

(6) inspect relief valve for scoring or

burrs.

Assembly

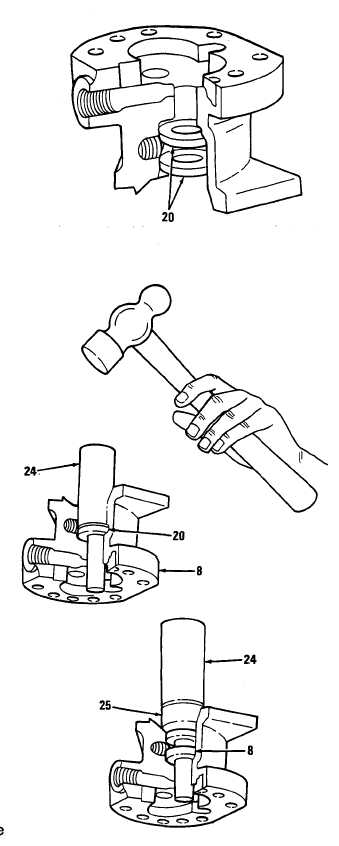

(1) Lubricate oil seals (20) with a thin

coat of clean engine oil or vegetable

shortening.

NOTE

Install new oil seals with seaI lips

facing each other. Refer to

illustration on right.

(2) Support fuel pump body (8) on wood

blocks. Using installer (24), install

inner oil seal (20) into fuel pump body

(8).

(3) Using adapter (25), install outer seal

(20) into fuel pump body (8).

(4) Lubricate outside diameter of relief valve

(18) with clean engine oil. Insert valve into

fuel pump body (8) with hollow end of valve

facing outward.

4 - 42 Change 1

|

|