TM 9-2815-202-34

4-19. BLOWER DRIVE GEAR AND SUPPORT REPLACEMENT (Cont)

d. Assembly

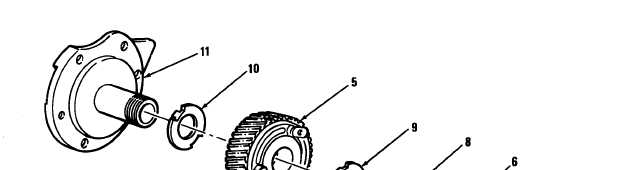

(1) Clamp blower drive gear support (11 ) in a soft-jawed vise with drive gear support shaft on

top.

(2) Lubricate blower drive gear support shaft (11), blower drive gear bearing (5) inside diameter,

thrust bearings (9 and 10), and thrust washer (8) with clean engine oil.

(3) Install thrust bearing (10) on drive gear support (11) with tang alined with slot in support,

(4) Install blower drive gear (5) on drive gear support (11) with flat side of gear towards support.

(5) Install thrust bearing (9) on drive gear support (11) with flat side towards gear (5).

(6) Install thrust washer (8) on drive gear support (11) with slots alined to tangs on thrust bearing

(9) and alining tab in slot of drive gear support shaft.

(7) Install lock plate (6) on drive gear support shaft (11) with alining tab in slot of shaft.

NOTE

Blower drive gear (5) must turn freely after torque is applied.

(8) Install nut (7) on drive gear support shaft and torque to 50-60 Ib-ft (68-81 N-m).

(9) Using a set of feeler gages, measure clearance between thrust washer (8) and thrust

bearing (9). Minimum allowable clearance is 0.005 and maximum allowable clearance is

0.010 inches for new parts or 0.012 inches for used parts.

(10) Bend tangs on lock plate (6) to secure nut (7).

4-64

|

|