TM 9-2815-202-34

4-23. REAR OIL SEAL REPLACEMENT (Cont)

b. Cleaning/Inspection

(1) Clean flywheel housing seal bore.

CAUTION

Do not polish parallel to crankshaft

or ridges will result and cause oil

leakage.

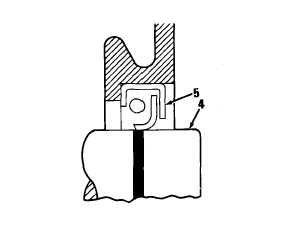

(2) Inspect rear end of crankshaft (4) for

wear due to rubbing action of oil seal

(5), dirt build up, or fretting by action

of flywheel. Remove slight ridges from

crankshaft by polishing with crocus

cloth in circular motion.

CAUTION

Rotate crankshaft in counterclockwise direction only. Do not rotate crankshaft bolt

clockwise or loosening will result.

(3) Check runout of seal bore by mounting a dial indicator on crankshaft and note reading while

crankshaft is rotated. Measure with flywheel housing installed on engine and seal removed.

Maximum runout of bore is 0.008 inch.

c. Installation

CAUTION

l

Crankshaft surface must be clean and smooth to prevent damage to seal lip when a

new seal is installed.

l

Do not scratch or nick sealing edge of oil seal or oil leakage past seal will result.

NOTE

If new seal is not precoated, apply a nonhardening sealant to metal casing.

(1) Coat lip of rear oil seal (5) with engine oil.

(2) Install two guide studs (6) and oil seal expander (7) to end of crankshaft.

(3) Position seal (5) with lip pointed toward inner face of housing. Slide seal over seal expander

(7) and onto crankshaft. Remove seal expander and guide studs.

(4) Using seal installer (8), guide studs (9), and driver handle (10), drive seal in place.

(5) Remove seal installer (8) and guide studs (9).

(6) Remove excess sealant from flywheel housing or seal.

4-78

|

|