TM 9-2815 -202-34

43

30

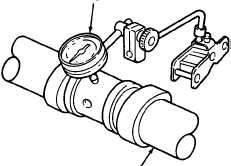

(3) Using dial indicator (43), measure runout of center camshaft journal with end journals

mounted on V-blocks. Replace camshaft if runout exceeds 0.002 inch.

l

(4) Check camshaft thrust surfaces for scoring or wear. Thrust surfaces maybe smoothed with

an crocus cloth if only slightly scratched.

(5) Examine faces of camshaft rear end bearings, thrust washers, and camshaft gear hubs for

scoring. Camshaft gear hubs not severely scored may be smoothed with an oil stone.

(6) Inspect bushings in end bearings for wear and scoring. Using calipers, measure outside

diameter of camshaft journals and inside diameter of camshaft end bearing bushings.

Difference must be between 0.0035 to 0.005 inch with new parts and a maximum of 0.006

inch with used parts.

(7) Inspect spacers and seal at front end of camshafts. Outside diameter of spacer on left bank

must provide a smooth oil seal contact surface.

(8) Inspect camshaft intermediate bearings. Replace bearings if excessively scored or worn.

Clearance between camshaft journals and intermediate bearings is 0.0025 to 0.005 inch

l

with new parts and a maximum of 0.009 inch with used parts.

(9) Examine intermediate bearing lock screws and tapped holes in cylinder block for damaged

threads.

l

(1 O) Inspect teeth on water pump drive gear and camshaft gears for scoring, pitting, and wear.

Examine keyways and tapped holes in gears and camshaft pulley for damage.

4 - 1 09

|

|