TM 9-2815-202-34

4-32. OIL PUMP REPLACEMENT (Cont)

e. Installation

(1)

(2)

(3)

(4)

(5)

(6)

(7)

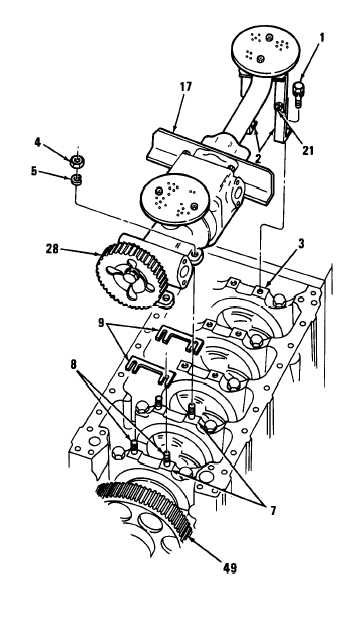

If removed, install four studs (8) into

main bearing caps (7).

Place same number of shims (9) as

were removed on main bearing caps

(7).

Position oil pump assembly (6) over

studs (8) and onto main bearing caps

(7 and 3). Aline teeth on spur gear

(30) with teeth on drive gear (49).

Secure oil pump assembly (6) with

four Iockwashers (5) and nuts (4).

Torque nuts to 26-29 Ib-ft (35-40

N-m).

Install two bolts (1) through brackets

(2) into rear main bearing cap (3).

Torque bolts to 23-26 Ib-ft (31-35

N-m).

Aline four brackets (2), eight flat

washers (22) and two self-locking

nuts (21 ). Torque nuts to 26-29 Ib-ft

(35-40 N-m).

With engine in upright position, check

gear tooth clearance between driven

gear (28) and drive gear (49). Using

dial indicator (50) mounted on

cylinder block, measure clearance.

Gear tooth clearance should be 0.006

to 0.012 inch.

NOTE

Shims control gear tooth clearance.

One set of 0.005 inch shims will

change gear tooth clearance by

0.0035 inch.

(8) If gear tooth clearance is not within

specifications, follow steps (a) thru

(d).

(a)

(b)

(c)

(d)

4-130

Invert engine.

Loosen four nuts (4) and two

bolts (1). Lift oil pump assembly

(6) enough to remove shims (9).

Install new quantity or correct

thickness of shims (9).

Repeat steps (4), (5), and (7).

|

|