TM 9-2815-202-34

(4) Check used liner for taper and out of round. Liner taper is difference between O.D. at 0.625

and 9.875 inches positions. Taper must not exceed 0.002 inch and out of round must not

exceed 0.0025 inch. If out of round exceeds 0.0025 inch, rotate liner 90 degrees in block

bore and recheck.

NOTE

Liners, standard and oversize, have an inside diameter of 4.2489 to 4.2511 inches.

Liners are available in 0.005, 0.010, 0.020, 0.030 inch oversize on outside diameter.

(5) When an oversize liner is installed, stamp amount of oversize on top of cylinder block bore

adjacent to liner counterbore.

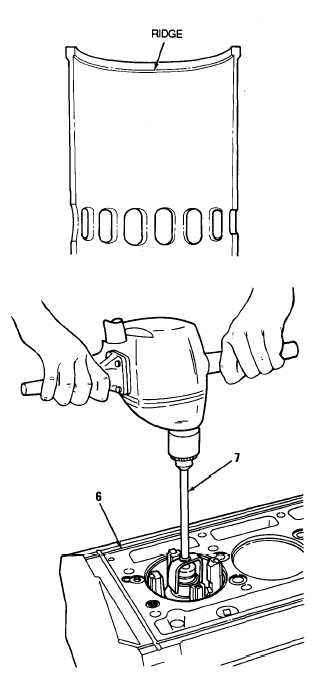

e. Honing

CAUTION

Do not modify surface finish of new liner. Liner is

properly finished at factory so changes will adversely

affect piston ring seating.

NOTE

Used cylinder liners must be honed to break glaze

resulting from extended operation and to remove

ridge formed at top of piston ring travel. If glaze is

not removed, time required to seat new piston rings

will be lengthened.

A scrap cylinder block makes an excellent honing

fixture.

(1) Place liner in fixture (6).

CAUTION

If liner is honed in block, completely dismantle engine

to insure all abrasive material is cleaned out.

(2) A hone (7) equipped with 120 grit stones should be

worked up and down full length of liner a few times

to produce a crisscross pattern of hone marks on 45

degree axis.

WARNING

Compressed air used for cleaning purposes

will not exceed 30 psi. Use only with effective

chip guarding and personal protective

equipment (goggles/shield, gloves, etc).

(3) Remove liner from fixture and clean thoroughly. Dry

with compressed air and check surface for burrs.

4-147

|

|