(5)

(6)

Immerse cylinder head in a tank of water

heated to 180o-200oF (82o-93oC) for

twenty minutes to heat head. Observe

water in tank for bubbles which indicate a

leak or crack. Check for leaks at top and

bottom of injector tubes, oil gallery,

exhaust ports, fuel galleries, and at top

and bottom of cylinder head.

Relieve air pressure and remove cylinder

head from water tank. Remove regulated

air supply, end plate, injectors, and

blocking plates from cylinder head.

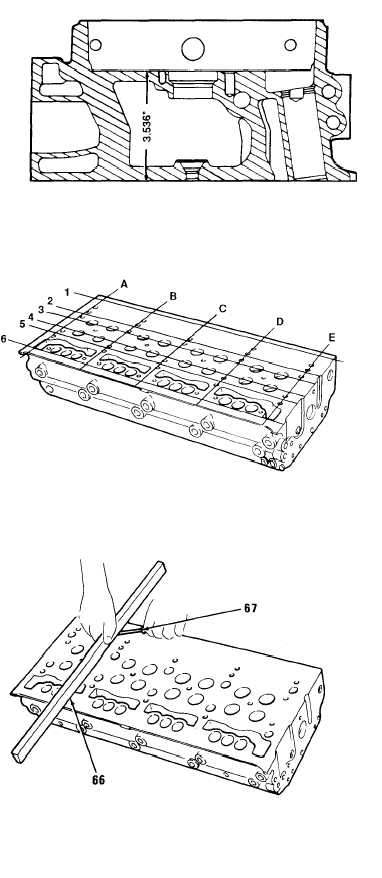

d. Inspection/Repair

NOTE

If warpage exceeds limits, reface cylinder

head. Do not remove more metal from fire

deck than minimum distance of 3.536

inches from top of deck to bottom of fire

deck.

(1) Cylinder head

(a)

(b)

Check fire deck surface of cylinder

head for flatness. Using a straight

edge (66) and a set of feeler gages

(67), check lengthwise (six places)

and crosswise (five places) warpage.

Maximum lengthwise warpage is

0.008 inch and maximum crosswise

warpage is 0.004 inch.

Inspect cam follower bores in

cylinder head for scoring and wear.

Clean light score marks with crocus

cloth wet with fuel oil. Measure

diameter of cam follower body and

cam follower bore to determine

clearance. Maximum clearance is

0.006 inch. Replace cylinder head if

bores are excessively worn or

scored.

(2) Water nozzles

Check water hole nozzles (68 and 69) for

looseness. If necessary, replace nozzles

as follows:

(a) Remove old nozzle (68 or 69) and

clean bore in cylinder head.

TM 9-2815-202-34

4-191

|

|