TM9-2815-202-34

(d) After grinding is completed, clean valve seat insert thoroughly. Measure concentricity of

insert in relation to valve guide. If runout exceeds 0.002 inch, check for bent or worn

valve guide before regrinding insert.

(e) Determine position of contact area between valve and valve seat insert as follows:

1. Apply a light coat of Prussian blue or equivalent to valve seat insert.

2. Lower stem of valve in valve guide and bounce valve on seat. Do not rotate valve.

3. Remove valve and observe area of contact on valve face. Most desirable area of

contact is at center of valve face.

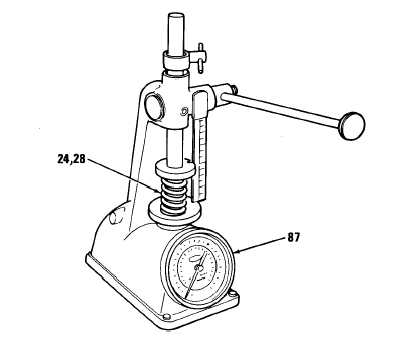

(7) Exhaust valves and springs

(a)

(b)

(c)

Insure valve stems are free from

scratches or scuff marks. Valve

faces must be free of ridges,

cracks, or pitting.

Replace valves if warped,

excessively worn, or pitted.

Using spring tester (87), replace

valve spring (28) when a load of

less than 25 Ibs will compress it

to 1.80 inches.

CAUTION

Replace both springs under an

exhaust valve bridge together.

Mating a new spring with a used

spring can cause unbalanced valve

operation.

(8) Cam followers and cam follower

springs.

(a) Examine cam follower springs

(24) for wear or damage. Using

spring tester (87), check spring

load. Replace spring when a load

of less than 172 Ibs will compress

it to a length of 2.125 inches.

4-197

|

|