TM 9-2815-202-34

5-14. ACCESSORY DRIVE REPLACEMENT (Cont)

c. Cleanlng/inspection

(1) Clean all parts with fuel

bearing.

WARNING

Compressed air used

oil except

for

cleaning purposes will not

exceed 30 PSI. Use only with

effective chip guarding and

personal protective equipment

(goggles/shield, gloves, etc.).

(2)

(3)

(4)

Dry all parts with compressed air.

Inspect fiber coupling and shaft

coupling half for cracks, wear, or

damage.

Inspect bearing and sleeve for scores,

pitting, or wear.

d. Assembly

(1)

(2)

(3)

(4)

(5)

(6)

(7)

5-18

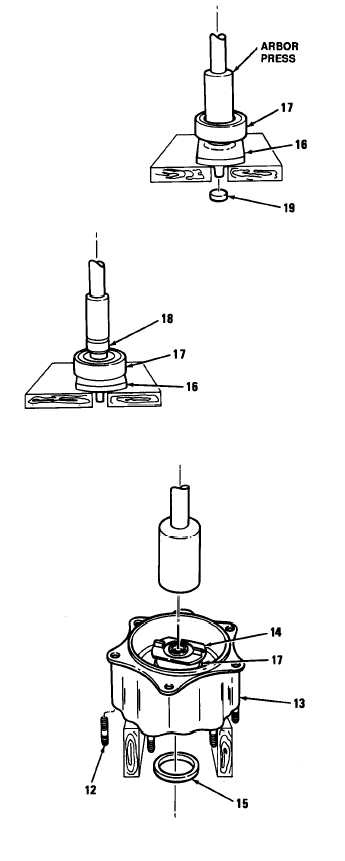

If removed, install cup plug (19) into

shaft coupling half (16).

Apply lubricant to each side of

bearing (17) prior to installing on shaft

coupling half (16).

Apply sealant to inner diameter of

bearing (17). Using arbor press, press

bearing onto shaft coupling half (16).

Apply sealant to inner diameter of

sleeve (18). Using arbor press, press

sleeve onto shaft coupling half (16).

Sleeve must be flush with end of

shaft.

Apply sealant to outer diameter of

bearing (17). Using arbor press, press

shaft coupling half assembly (14) into

accessory drive housing (13).

If removed, install seal (15), part

number out, into accessory drive

housing (13).

If removed, install six studs (12) into

accessory drive housing (13). Torque

studs to 12-17 Ib-ft (1 6-23 N-m).

|

|