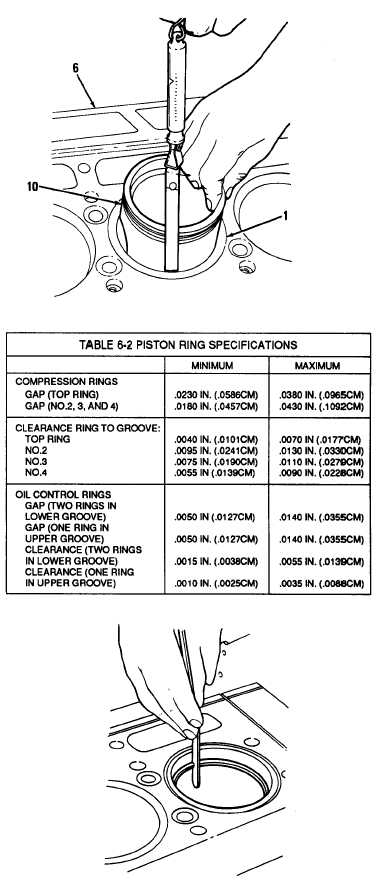

TABLE 6-2

TM9-2815-202-34

6-34. PISTON AND CONNECTING ROD MAINTENANCE (TRUNK TYPE) (Cont)

•

•

(2)

(3)

NOTE

Use feeler gage to check piston to

liner clearance. Use a spring scale

attached to feeler gage to measure

amount of force in pounds required

to withdraw feeler gage from

between piston and liner. Select

feeler gage with thickness requiring

six pounds pull to move. Piston to

liner clearance is 0.001 inch greater

than thickness of feeler gage used.

For example, a 0.004 inch feeler

gage indicates 0.005 inch clearance

when withdrawn with a six pound

pull.

Feeler gage must be perfectly flat

and free of nicks and bends.

With cylinder liner (1) installed in

cylinder block (6), hold piston (10)

upside down in liner and measure

clearance in four places, 90 degrees

apart. Clearance must be 0.0045 to

0.0083 inch with new parts. Allow a

maximum clearance of 0.0120 inch

for used parts.

If binding occurs between piston and

liner, remove piston and examine

piston and liner for burrs. Remove

burrs on piston with a fine stone.

Remove burrs in liner with fine flat

hone and recheck clearance.

f. Fitting Piston Rings

(1) Insert ring inside cylinder liner in

normal area of ring travel. Using

piston to push ring down, measure

ring gap with feeler gage. Refer to

Table 6-2 for ring gap specifications.

Repeat procedure for balance of

compression and oil rings.

File or stone both ends of

compression ring from outer surface

to inner surface to prevent chipping

or peeling of chrome plating on ring.

(2) File ends of compression ring if ring

gap is too small. Ends of ring must

remain square, and chamfer on outer

edge must be approximately 0.015

inch.

6-36

|

|