TM9-2815-202-34

6-34. PISTON AND CONNECTING ROD MAIN

TENANCE (TRUNK TYPE) (Cont)

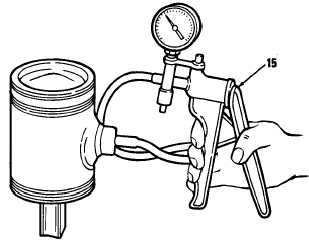

(f) Check each piston pin retainer for

proper sealing with leak detector

(15). Place suction cup over

retainer and hand operate lever

to pull a vacuum of ten inches of

mercury on gage. A drop in gage

reading indicates air leakage at

retainer.

(2) Installation - Piston Rings

NOTE

Before installing piston rings,

assemble piston and rod as directed

in previous section.

(a) Lubricate piston rings and piston

l

l

with engine oil before installing

rings.

CAUTION

Do not overlap ends of oil control ring expanders. An overlapped expander will

cause oil control ring to protrude beyond allowable limits and result in breakage

when inserting piston in ring compressor.

Do not cut or grind ends of expanders to prevent overlapping. Cutting or grinding

ends will decrease expanding force on oil control rings and result in high-lubricating

oil consumption.

NOTE

Scraper edges of all oil control rings must face downward (toward bottom of piston) for

proper oil control.

(b) Install two ring expanders (16) in oil control ring grooves in piston (10). Install oil ring

expanders with legs of free ends toward top of piston.

WARNING

Do not grasp or graze sharp edges of oil control rings with bare hands.

Rings are extremely sharp and can cut personnel when mishandled.

l

l

6-38

NOTE

Upper oil control ring groove requires a one-piece

two-piece ring (upper and lower halves).

Install upper and lower oil control rings by hand.

ring, and lower groove requires a

Scraper edges of all oil control rings must face downward (toward bottom of piston)

for proper oil control.

|

|