| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

ROCKER ARM ASSEMBLY AND COVER REPAIR

0105 00

CLEANING

1. See Work Package 0028 for General Cleaning Procedures.

INSPECTION

All parts must be inspected with care. Replace parts if damage or wear exceeds allowable

limits.

1.

See Work Package 0028 for General Inspection Procedures.

2.

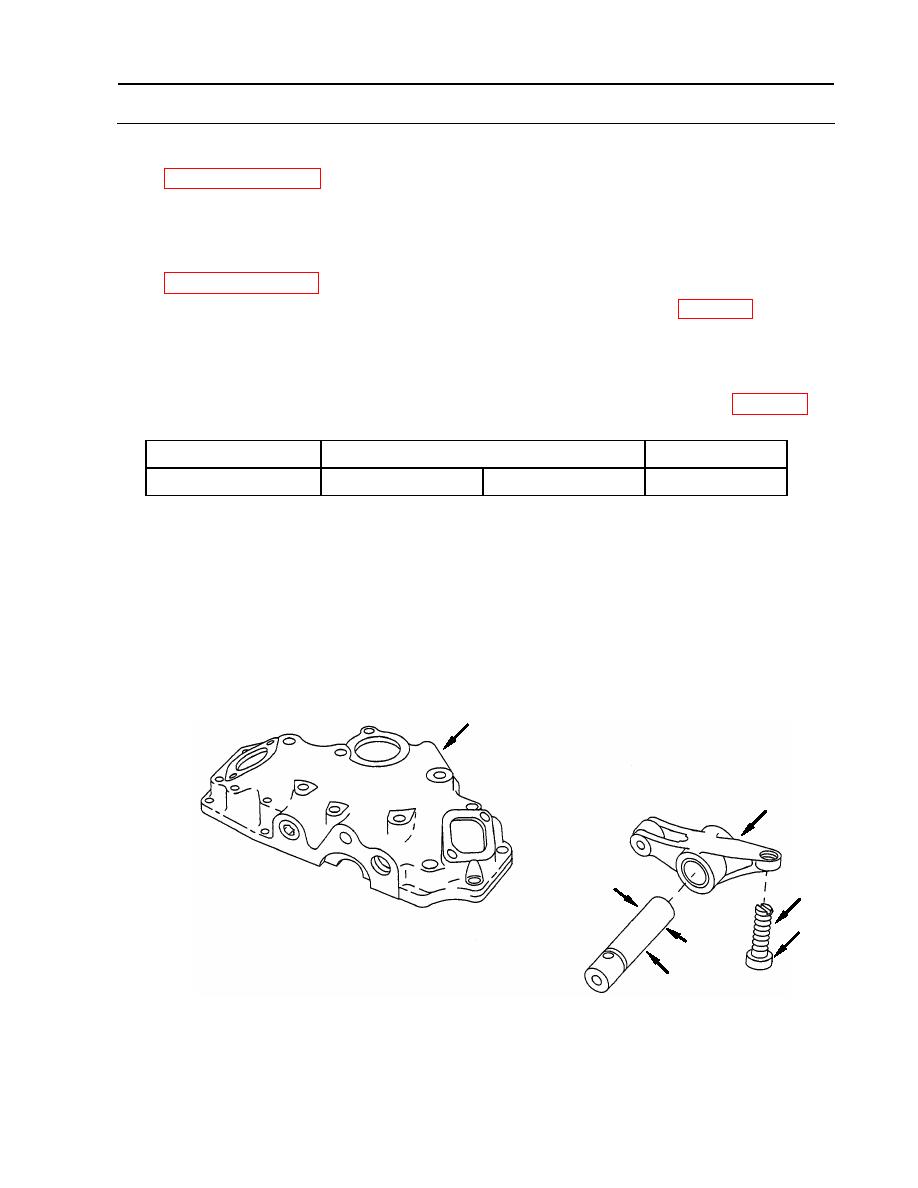

Inspect rocker arm cover (2) for cracks using a magnifying glass (item 73, WP 0176) and a

strong light. Replace any cracked rocker arm cover.

3.

Check straight shaft (5) for cracks, scores, and metal pick up or plugged oil passages. Replace

any cracked, deeply scored, or plugged straight shafts.

4.

Measure outside diameter of straight shaft (5) using outside micrometer (item 17, WP 0176).

Replace straight shafts that do not meet the following limits:

Location

Sizes and Fits of New Parts inches (mm)

Wear Limits

A (Shaft diameter)

0.7480 (18.9992)

0.7485 (19.0119)

0.7470 (18.9738)

5. Inspect adjusting screw (7) for stripped or damaged threads. Replace adjusting screw if

damaged.

6. Check adjusting screw (7) by turning in and out of rocker arm (1). Replace adjusting screw (7)

that does not turn freely.

7. Check swivel pad (B) for free rotation on adjusting screw (7). Replace adjusting screw (7) if

swivel pad (A) does not rotate freely.

2

1

A

7

B

5

WP 0105 00-3

|

||

|

||