| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

CRANKSHAFT MAIN BEARINGS INSPECTION

0138 00

INSPECTION (Continued)

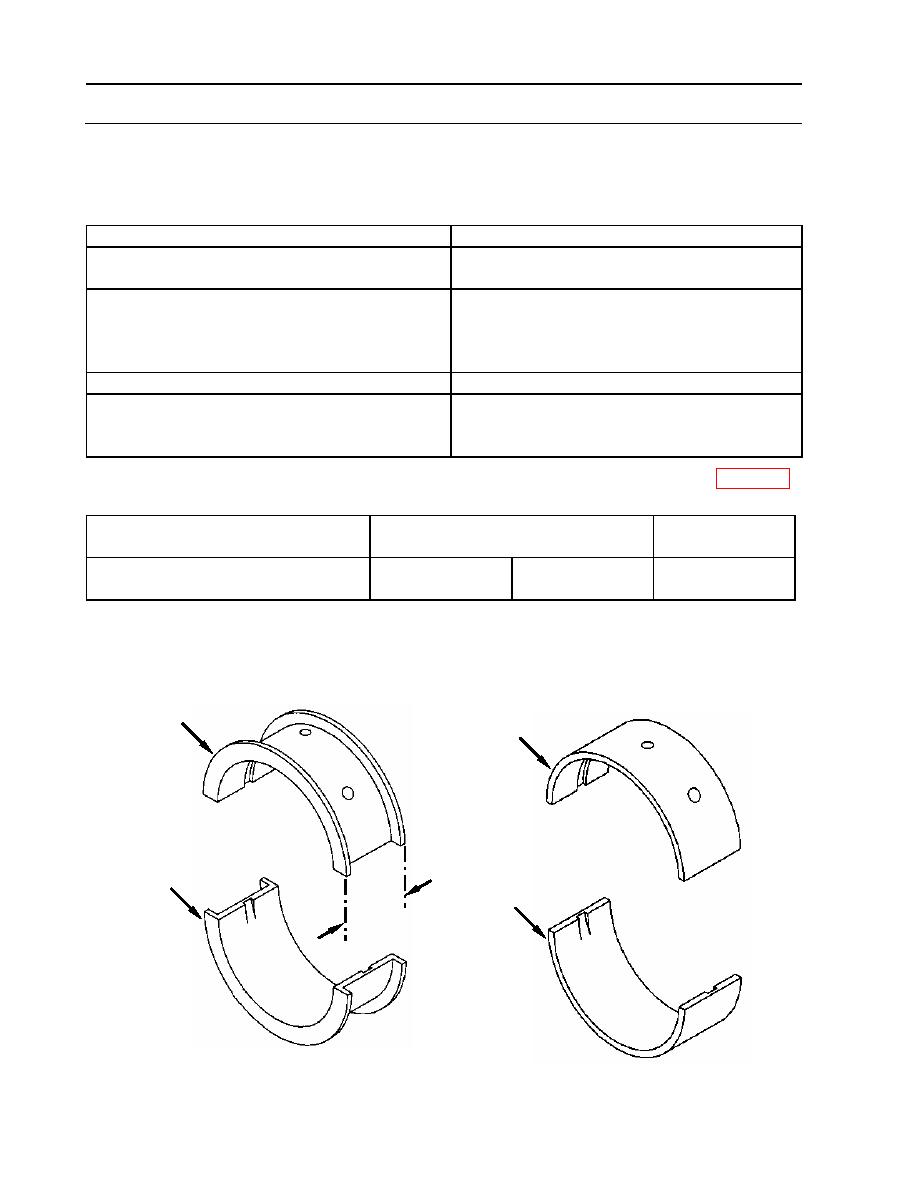

1. Visually inspect used main bearing halves (1, 2, 3, and 4) to the following table. If any

bearing is questionable, replace it.

Basis for Bearing Rejection

Acceptable Bearing Flaws

Separation of bearing metal, or signs of possible Fine scratches on bearing surface.

separation.

Pitting or any other form of destruction to

Minute pieces of metal and dirt particles

bearing surface.

embedded in bearing surface with a

concentration of less than 5 percent. (Do not

attempt to remove such particles.)

Raised metal at edges of scratches.

Pieces of metal or dirt particles embedded in

bearing surface with a concentration of

5 percent or more of the surface area.

2. Measure outside width (A) of main thrust bearing (1, 2) using micrometer (item 17, WP 0176).

Replace bearings that do not meet the following limits:

Point of Measurement

Sizes and Fits of New Parts

Wear Limits

inches (mm)

A (Outside width of main thrust

2.4860 (63.1444) 2.4880 (63.1952) 2.4840 (63.0936)

bearing)

1

3

A

2

4

WP 0138 00-2

|

||

|

||