| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

PISTONS, RINGS, AND ASSOCIATED PARTS REPLACE/REPAIR

0142 00

INSPECTION (Continued)

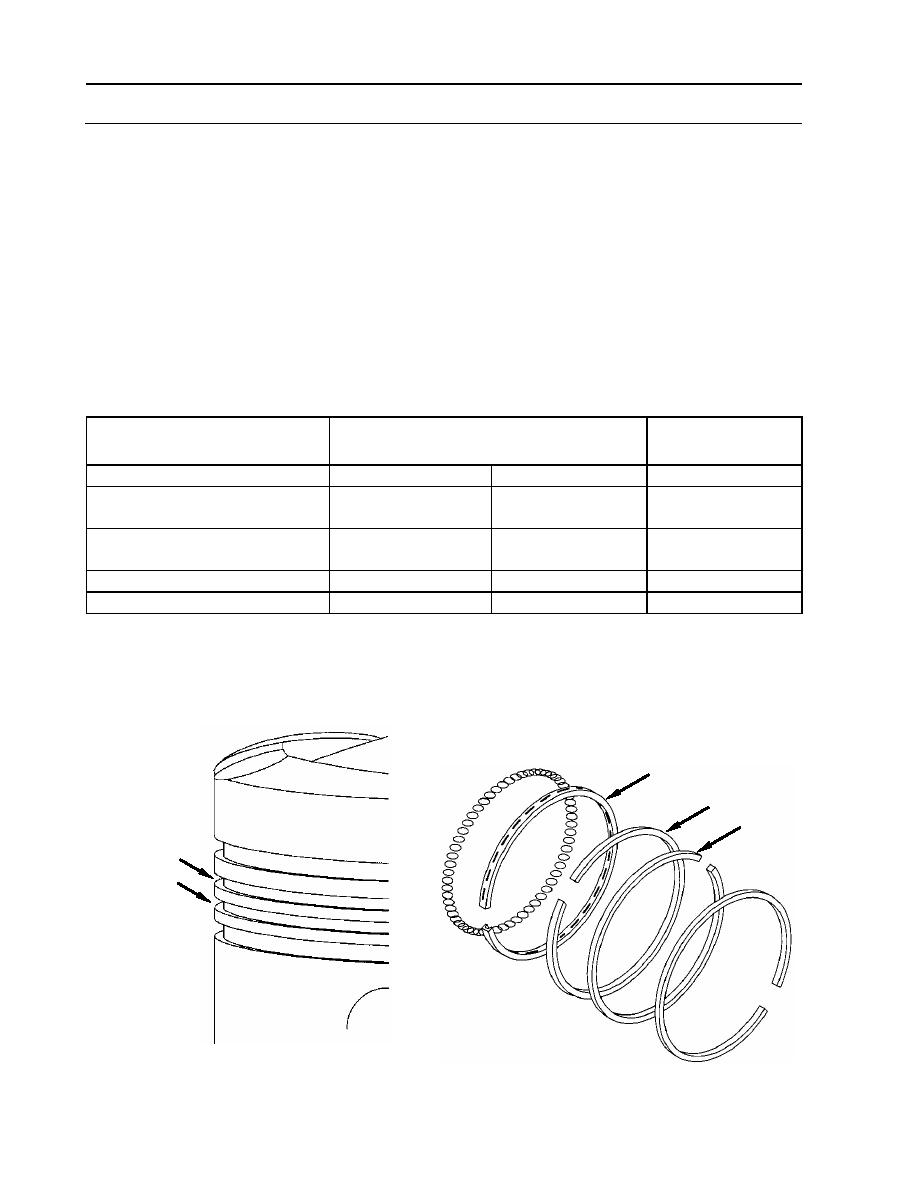

7. Visually inspect piston rings.

a. Look for scuffing, scoring, chipping, scratches or abrasions. Pay particular attention to

rings that were found to be sticking in the piston ring grooves.

b. Replace any rings that are scuffed, scored, chipped, or abraded.

NOTE

The width of the top piston ring cannot be accurately measured.

When ring is installed in fixture, the end gap is the only measurement

for the top ring.

8. Measure the width of intermediate compression rings (2) and oil control ring (3). Replace

rings that do not meet the following limits.

Location

Sizes and Fits of New Parts

Wear Limits

inches (mm)

2 (Compression ring width)

0.0925 (2.3495)

0.0935 (2.3749)

None

2 (Clearance when installed in

0.0055L (0.1397L)

0.0075L (0.1905L) 0.0110 (0.2794)

second (A) ring groove)

2 (Clearance when installed in

0.0045L (0.1143L)

0.0065L (0.1651L) 0.0100 (0.254)

third (B) ring groove)

3 (Oil control ring width)

0.1855 (4.7117)

0.1865 (4.7371)

None

3 (Clearance when installed)

0.0015L (0.0381L)

0.0035L (0.0889L) 0.0055L (0.1397L)

NOTE

Clearances (A and B) will be measured with a thickness gauge at

assembly.

3

2

2

A

B

WP 0142 00-8

|

||

|

||