| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

PISTONS, RINGS, AND ASSOCIATED PARTS REPLACE/REPAIR

0142 00

INSPECTION (Continued)

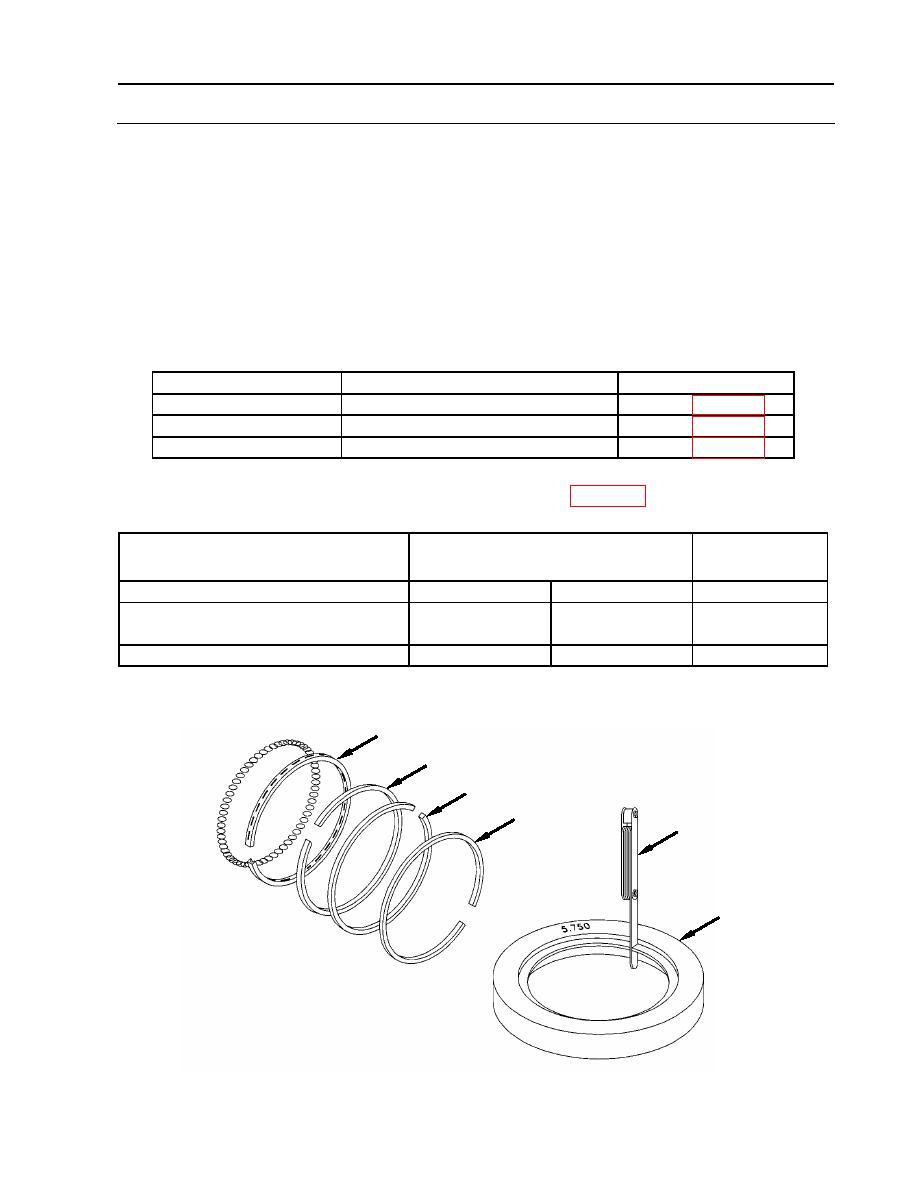

9. Measure ring end gap.

a. Place each ring (1, 2, 3, 4) one at a time, in the appropriate ring gauge (9) (standard or

oversize).

NOTE

Ring gauges are identified according to ring size. Some gauges are

duel purpose tools; i.e., each side for a different size ring. Select the

proper ring gauge from the following table.

Gauge Identification

Ring Size Identification

Ring Gauge

5.7500 and 5.7700

Standard and 0.020 in. oversize

Item 48 (WP 0176)

5.7600 and 5.7800

0.010 and 0.030 in. oversize

Item 45 (WP 0176)

0.7500 and 5.7900

Standard and 0.040 in. oversize

Item 46 (WP 0176)

b. Measure end gap with a thickness gauge (10) (item 54, WP 0176). Replace rings that do

not meet the following limits.

Location

Sizes and Fits of New Parts

Wear Limits

inches (mm)

1. (Top compression ring)

0.0250 (0.635)

0.0350 (0.889)

0.0350 (0.889)

2. (Intermediate compression rings

0.0250 (0.635)

0.0350 (0.889)

0.0350 (0.889)

2nd and 3rd groove)

3. (Oil control ring)

0.0350 (0.889)

0.0450 (1.143)

0.0450 (1.143)

3

2

2

1

10

9

WP 0142 00-9

|

||

|

||