| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

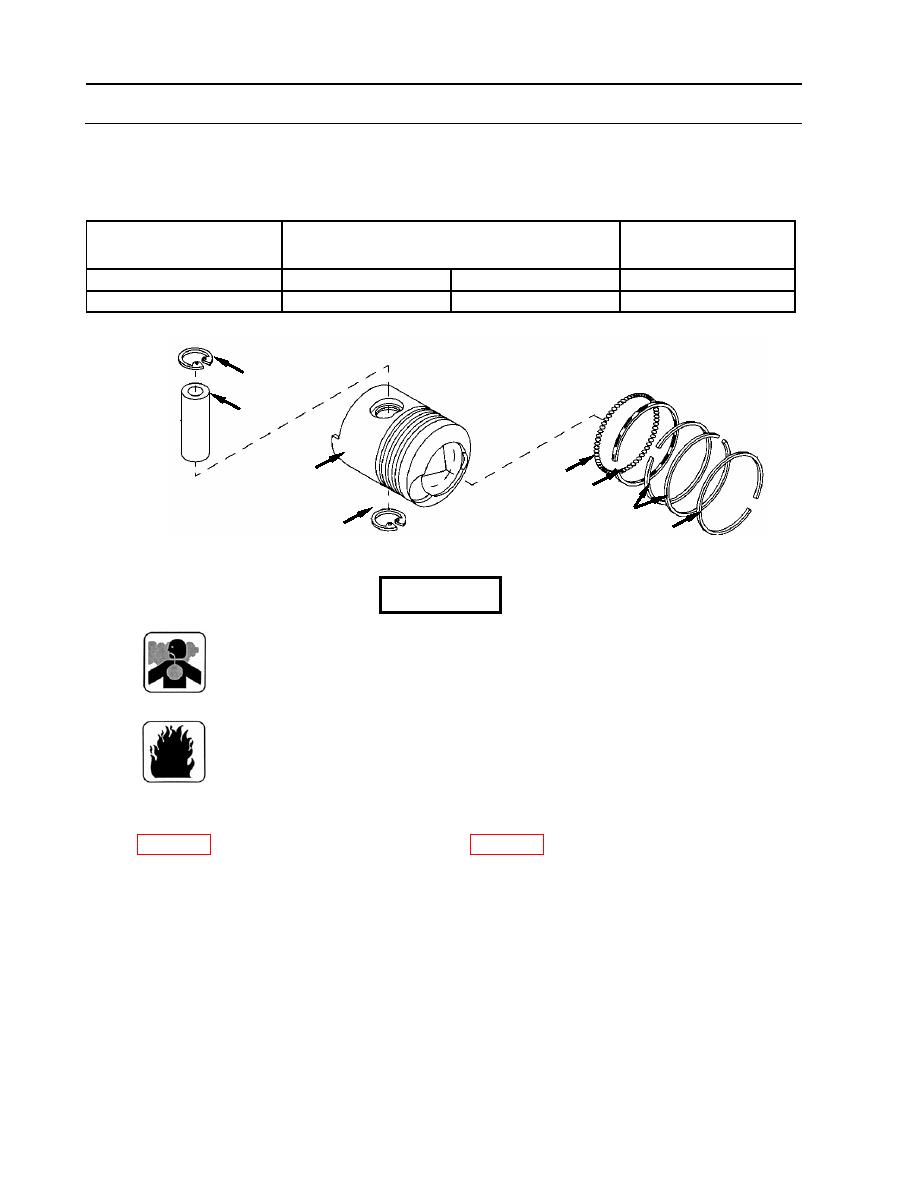

PISTONS, RINGS, AND ASSOCIATED PARTS REPLACE/REPAIR

0142 00

INSPECTION (Continued)

10. Inspect piston pin (7).

a. Check diameter of piston pins (7) against limits specified below.

Location

Sizes and Fits of New Parts

Wear Limits

inches (mm)

A (Diameter of pin)

2.1250 (53.975)

2.1252 (53.9800)

2.1248 (53.9699)

Fit of pin to bore

0.0016L (0.0406L)

0.0020L (0.0508L)

0.0032L (0.08128L)

8

7

4

6

3

2

8

1

REPAIR

WARNING

Cleaning solvent is mildly toxic. Solvent evaporates and both the

fumes and liquid are flammable. Continued contact with solvent

can cause skin problems.

Ensure there is good airflow when using solvent, and work area is

away from heat and flames.

Keep fire extinguisher nearby.

Do not breathe solvent fumes.

Avoid skin contact. See Warning in front of Manual.

1. Remove minor burrs, nicks or scratches from pistons (4) with crocus cloth (item 9,

2. Replace pistons (4) that are distorted, cracked, worn, or abraded.

3. Replace pistons (4) if oil holes in the ring grooves cannot be cleared or if lands are

damaged or broken.

4. Replace pistons (4) that are badly burred or scratched.

5. Replace piston rings (1, 2, 3, or 4) that are scuffed, chipped, scratched, or showing signs of

abrasion.

6. Replace oil control rings (3) if drain holes cannot be cleared.

WP 0142 00-10

|

||

|

||