| Tweet |

Custom Search

|

|

|

||

TM 9-2815-220-24

ACCESSORY DRIVE HOUSING REPLACE/REPAIR

0158 00

CLEANING

1. See Work Package 0028 for Standard Cleaning Procedures.

INSPECTION

All parts must be inspected with care. Replace parts if damage or wear exceeds allowable

limits.

1.

See Work Package 0028 for Standard Inspection Procedures.

2.

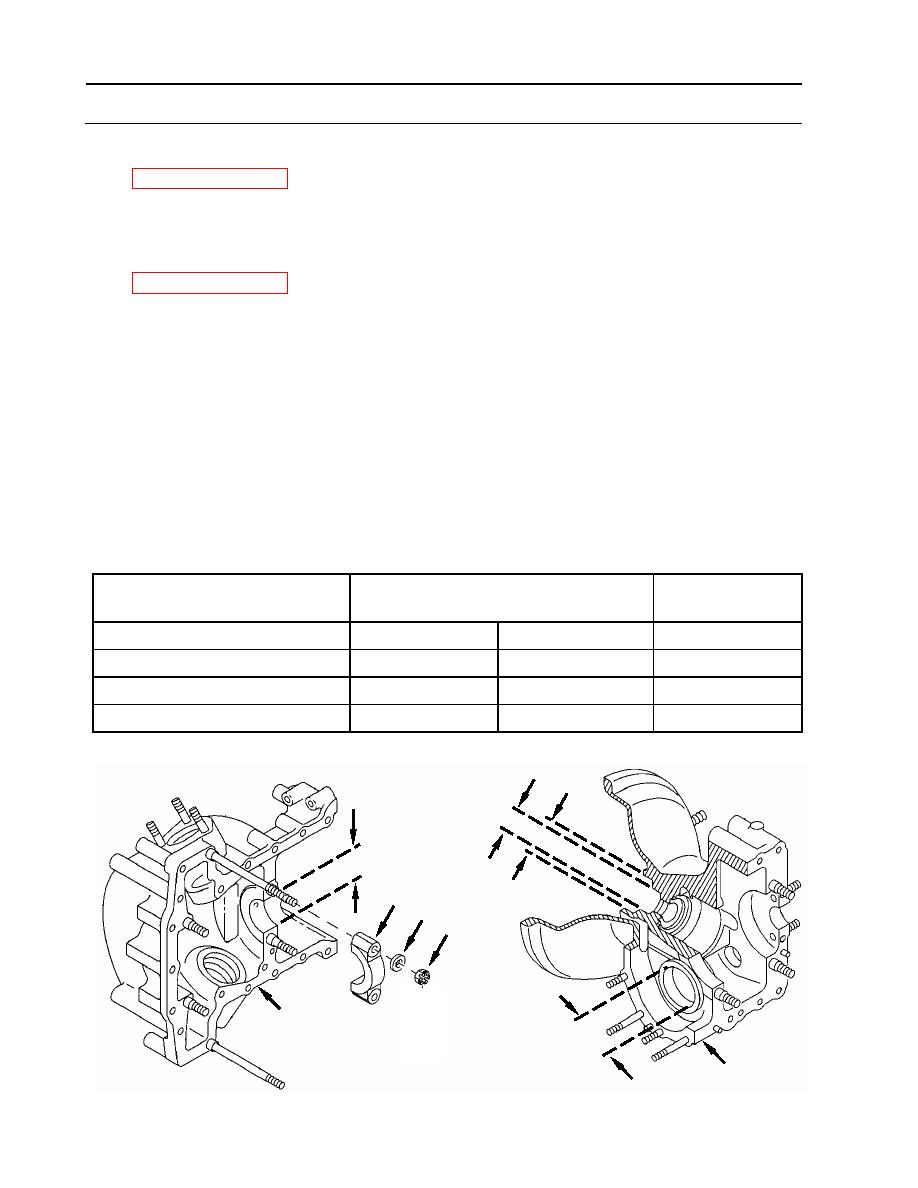

Measure inside diameter of accessory drive (9) bearing bore.

a. Install bearing cap (20) and secure using two nuts (18) with flat washers (19).

b. Tighten two nuts (18) to 275-300 inch-pounds.

c. Measure inside diameter (A).

d. Replace housing and bearing cap if not within specifications in the following table.

3.

Measure inside diameter (B) of liner in rear fan drive housing (8). Replace housing if not

within specifications in the following table.

4.

Measure inside diameter (C) of small upper liner in housing (8). Replace housing if not within

specifications in the following table.

5.

Measure inside diameter (D) of large upper bearing bore in housing (8). Replace housing if

not within specifications in the following table.

Location

Sizes and Fit of New Parts

Wear Limits

inches (mm)

A (accessory housing bore)

2.3770 (60.3758)

2.3780 (60.4012)

2.3790 (60.4266)

B (liner, rear fan housing)

2.4409 (61.9989)

2.4416 (62.0166)

2.4419 (62.0243)

C (upper liner, rear fan housing)

1.1440 (29.0576)

1.1460 (29.1084)

1.1465 (29.1211)

D (bearing bore)

2.9528 (75.0011)

2.9535 (75.0189)

2.9538 (75.0265)

C

D

A

20

19

18

9

8

B

WP 0158 00-10

|

||

|

||