| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

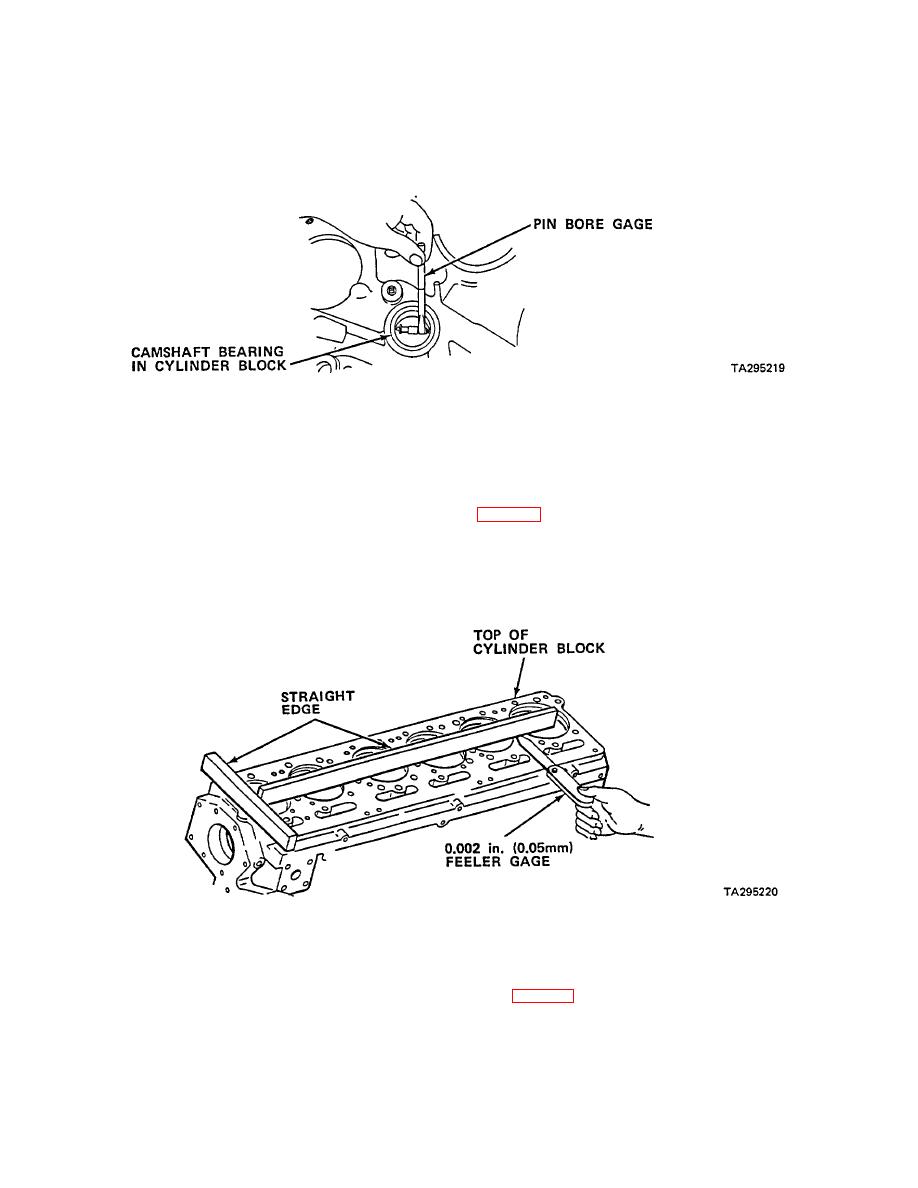

g. Check camshaft bearings:

(1) Inspect camshaft bearings for chips, scoring, or cracks. If defective, mark for replac ement.

(2) Measure inside diameter of each camshaft bearing to determine amount of wear.

(3) Mark for replacement if diameter is greater than 2.5008 in. (63.5203 mm).

(4) If bearing has turned in block bore (oil hole in bearing not alined with hole in block bore) measure inside

diameter of bore with bushing removed. Refer to para 3-6f(35) for bearing removal.

(5) Replace cylinder block if inside diameter is gre ater than 2.6265 in. (66.7131 mm).

h. Check block top flatness.

(1) Place straightedge on top of block to check flatness from front to rear and left to right.

(2) Using a 0.002 in. (0.050 mm) feeler gage, try to insert gage between straightedge and block. If clearance

greater than 0.002 in., top surface must be resurfaced (para 3-9a).

3-61

|

||

|

||