| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

o. Check cylinder head bolt threads.

(1) Inspect cylinder head bolt threads for damage.

(2) Mark damaged threads for installation of solid bushing-type threaded ins erts (para 3-9j).

3-9. REPAIR CYLINDER BLOCK

a. Top surface refinishing.

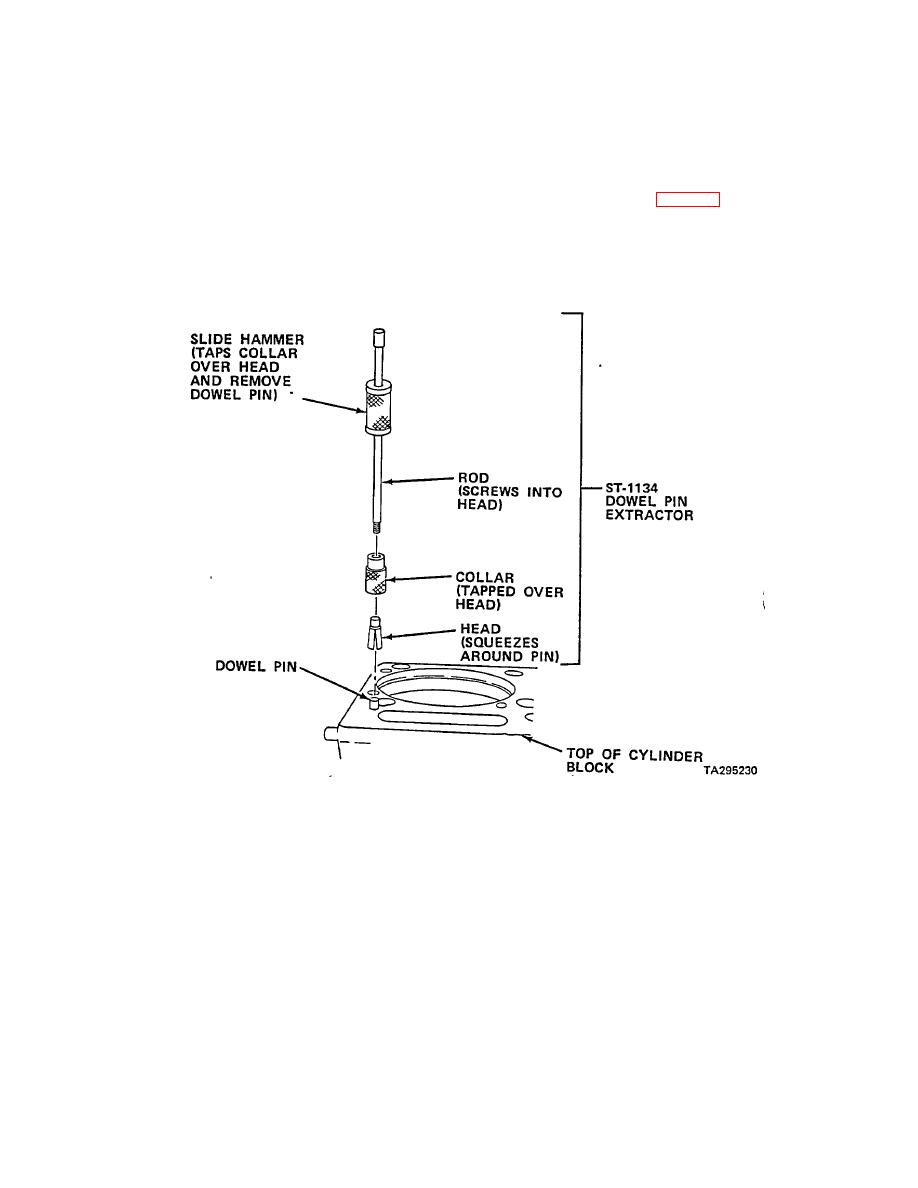

(1) Remove all dowel pins from top of block using ST-1134 dowel pin extractor. Extractor has several size

heads to fit various size dowel pins.

(2) Using large surface grinder, set up cylinder block using main bearing saddle pads for surface alinement.

CAUTION

DO NOT USE DISC SANDER.

MAY RESULT IN UNEVEN GASKET SEALING

SURFACE.

(3) Make light cuts of 0.001 to 0.003 in. (0.02 5 to 0.076 mm) deep removing only enough material to make

block serviceable. Maximum material that can be removed is 0.010 in. (0.254 mm). Finish material with

orbital sander to 125 microfinish.

3-70

|

||

|

||