| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-1

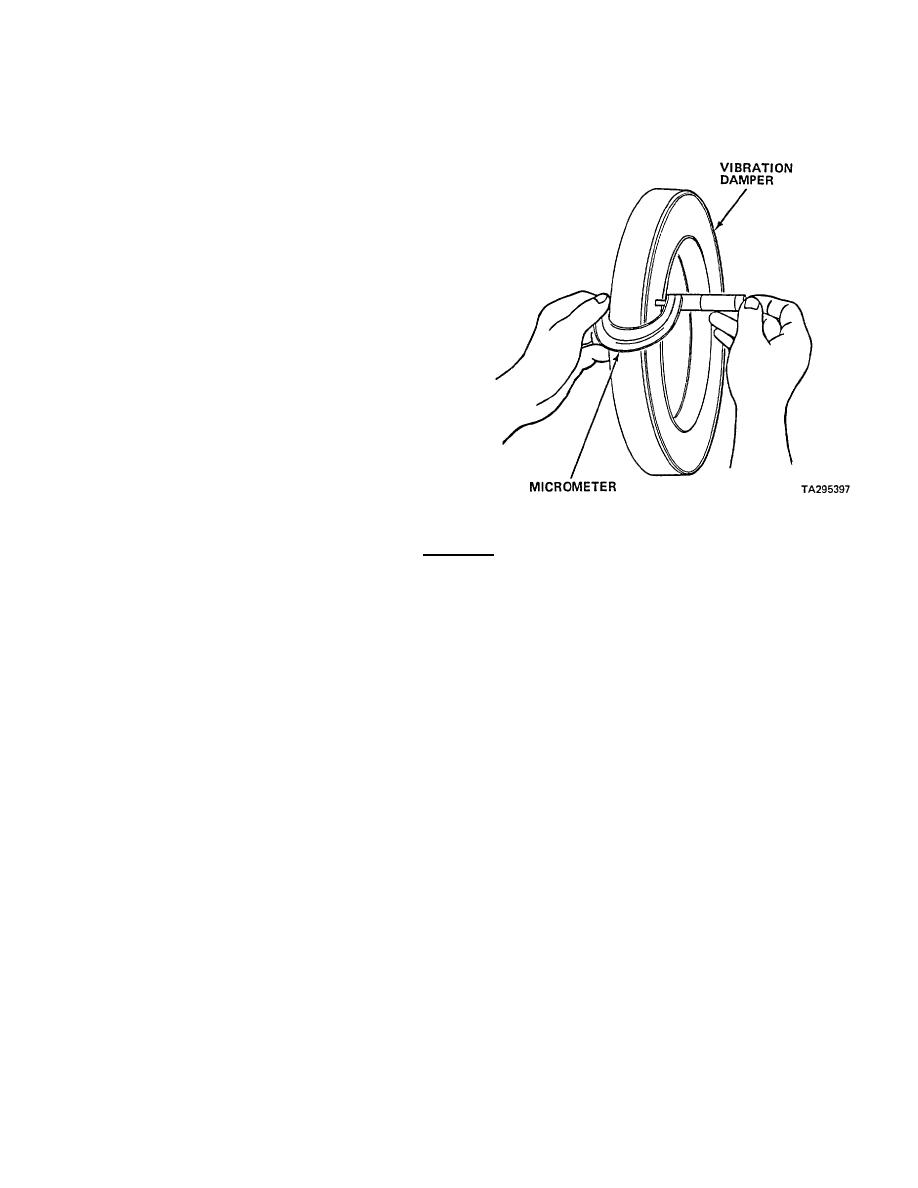

(1) Remove paint with fine (240 grit) emery

cloth from front and rear surfaces of

damper at four equally spaced areas.

Avoid areas with stamped lettering.

(2) Measure and record thickness of damper

at each of the equally spaced areas

approximately 0.125 in. (3.175 mm) from

outside edge of front cover plate.

(3) Replace damper if variations of four

dimensions exceed 0.010 in. (0.254 mm).

(4) Spray damper with Spotcheck Developer,

Type SKD-NF.

(5) Place damper in oven heated to 200 F

(93C) for 15 minutes.

WARNING

USE GLOVES TO PROTECT HANDS FROM BURNS.

HANDLE DAMPER WITH

CARE.

(6) Remove damper from oven.

(7) Inspect for oil smudges or fluid leakage.

(8) Replace damper if smudges or leakage is detected.

d. Inspect pulley.

NOTE

Pulley is not repairable. If inspection shows defects, replace pulley.

(1) Check pulley grooves for chips or cracks.

(2) Check gr ooves for wear with new belt. Belt must not bottom in groove.

(3) Discard pulley if defective.

3-225

|

||

|

||