| Tweet |

Custom Search

|

|

|

||

TM 9-2815-226-34-2

NOTE

If 1/2 in. (12.7 mm) Grade 8 capscrews are used, torque capscrews to 115-125 ft lbs

(156-170 N m). If 5/8 in. (15.88 mm) Grade 8 capscrews are used, torque capscrews

to 180-200 ft lbs (244-271 N m). If 5/8 in. (15.88 mm) Grade 5 capscrews are used,

torque to 150 - 170 ft lbs (203 - 231 N m).

(4)

Coat capscrews with oil and secure damper assembly to crankshaft.

Torque capscrews to

specifications as noted above.

(5)

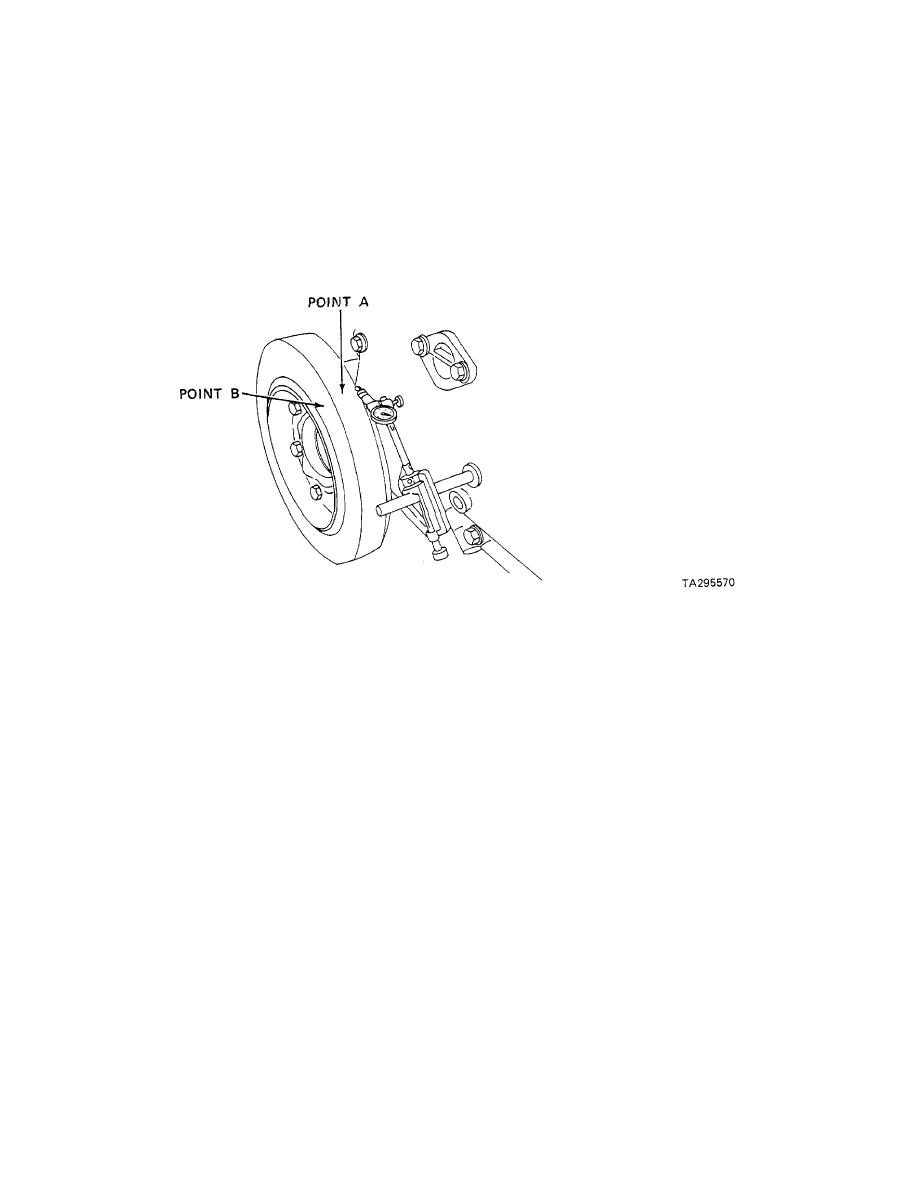

Position dial indicator contact pin against outside surface of vibration damper (Point A). Zero

indicator.

NOTE

Use accessory drive pulley nut to rotate engine.

(6)

Rotate crankshaft so that indicator measures run-out of 1 in. (25.4 mm) distance.

(7)

Run-out must not exceed 0.0025 in. (0.0635 mm).

(8)

If run-out exceeds specification, replace damper.

(9)

Relocate indicator so that its contact pin acts against front face of damper (Point B).

(10)

Rotate crankshaft so that indicator measures amount of damper wobble over a 1 in. (25.4 mm)

distance.

3-440

|

||

|

||