TM 9--2815--247--34

0061 00--6

CYLINDER HEAD ASSEMBLY REPAIR -- CONTINUED

0061 00

Inspection -- Continued

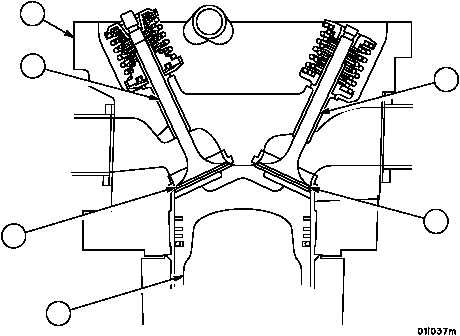

3. Inspect valve seat inserts (19 and 20) for cracks, pitted surfaces, or looseness.

NOTE

If inserts are cracked, loose, or damaged beyond repair,

the cylinder must be replaced.

4. Lightly blue face of two valve seat inserts (19 and 20) with Prussian blue and place a new valve (9 and 13) into

position on valve seat insert.

5. Rotate valves (9 and 13) one--half turn on insert and check for Prussian blue contact. Valve seat inserts (19 and

20) must show contact all around (360°), as indicated by Prussian blue transfer, to qualify as serviceable valve

seat inserts (19 and 20).

NOTE

Valve seat may be made serviceable by grinding.

NOTE

Measure cylinder bore (21) at room temperature.

Standard and oversize cylinder assemblies are identified

by the steel stamped part number located on cooling fan

shroud bracket mounting flange on exhaust port side of

the cylinder assembly (22).

Figure 9

INTAKE

EXHAUST

19

20

9

13

21

22

|

|