TM 9--2815--247--34

0069 00--5

PISTONS, RINGS, AND ASSOCIATED PARTS REPAIR -- CONTINUED

0069 00

Inspection -- Continued

NOTE

If Zyglo penetrant kit is available, use of the Zyglo method

is preferable. Small cracks will show under the light as

irregular or dark streaks.

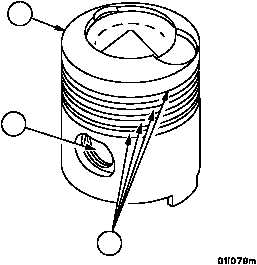

3. Inspect piston (10) for cracks, flaws or distortion, using a magnifying glass and a strong light.

4. Inspect piston (10) for damage or broken ring lands (15), nicks, or burrs.

5. Inspect piston pin bores (16) for wear, cracks, or abrasions.

6. Measure the inside diameter of piston pin bore (16). Replace pistons that do not meet the following limits.

REF

NO.

POINT OF MEASUREMENT

SIZES AND FITS OF NEW PARTS

inches (mm)

WEAR LIMITS

16

Inside diameter of piston pin bore

in piston

2.1268 (54.0207)

2.1270 (54.0258)

2.1280 (54.0512)

Figure 8

10

16

15

|

|